Nichrome wire is a remarkable material with a unique combination of properties that make it indispensable across a broad range of industries and applications. Known for its high resistance to heat and excellent electrical conductivity, nichrome wire is an alloy composed primarily of nickel and chromium. This powerful duo creates a material that can endure extreme temperatures without breaking down, making it the go-to choice for heating elements, resistors, and cutting tools. Whether you’re an industrial manufacturer or a DIY enthusiast, nichrome wire offers unparalleled performance and reliability for projects that demand durability and precision.

One of the key features of nichrome wire is its ability to maintain stability at high temperatures. This property has solidified its role in the production of heating devices such as toasters, hairdryers, and industrial furnaces. However, its utility extends far beyond heating. Nichrome wire’s consistent resistance also makes it a favorite in electrical engineering, where precise voltage control is essential. Even in creative pursuits like foam cutting and sculpture, nichrome wire has become a staple for its flexibility and reliability.

At The Crazy Wire Company, we’ve dedicated ourselves to providing the highest quality nichrome wire for every imaginable use. In this guide, we will delve into what nichrome wire is, how it works, and why it’s such a valuable material. From its composition and properties to its many applications and benefits, this article will give you everything you need to know about nichrome wire.

Whether you’re looking to purchase nichrome wire for your next project or simply want to learn more about this fascinating material, read on to discover the incredible potential of nichrome wire.

What Is Nichrome Wire?

Nickel and chromium are the main components of nichrome wire, also known as nickel chrome. It is an alloy produced by combining nickel with chromium and sometimes iron. In addition to a being heat resistant metal, nichrome wire is also resistant to corrosion and oxidation which makes it a long-lasting material therefore useful for many purposes including commercial products, crafts and tools.

How To Use Nichrome Wire

Nichrome can be found in household items such as toasters and hair dryers as it’s a great heating element since it resists heat and oxidation. Ceramic sculpturing and glassmaking are also popular hobbies that use nichrome wire. In addition to laboratories, construction and specialised electronic applications, the wire is also perfect for using in DIY projects.

Nichrome Alloy

Nickel chromium alloy wires are produced using a range of different methods depending on their intended use however the most common forms of nichrome wires are Ni60 which is composed of 60 percent nickel and 40 percent chromium. The same principle goes for other common forms such as Ni80, Ni90 and Ni200 wire however the properties of all nichrome alloys remain the same regardless of their nickel/chromium ratio. When heated, nichrome forms a thin layer of chromium oxide that prevents it from oxidizing. This makes it resistant to both heat and corrosion in and out of water.

Technical Specification of Nichrome:

- Ni – Rest

- Cr – 20.0 – 23.0

- Fe – <1.0

- Max Continuous Service Temp Of Element – 1200

- Micrographic Structure – Austenite

- Magnetic Properties – Nonmagnetic

- Electrical resistance is high

- Corrosion resistance is high

Available Nichrome Wire Options:

| Ni80 | Ni80 | Ni90 | Ni90 | Ni60 | Ni60 |

| Diameter (mm) | AWG | Diameter (mm) | AWG | Diameter (mm) | AWG |

| 0.05 | 44 | ||||

| 0.06 | 42 | ||||

| 0.07 | 41 | ||||

| 0.08 | 40 | 0.08 | 40 | ||

| 0.09 | 39 | ||||

| 0.1 | 38 | 0.1 | 38 | ||

| 0.12 | 36 | ||||

| 0.125 | 36 | ||||

| 0.13 | 36 | 0.13 | 36 | ||

| 0.14 | 35 | ||||

| 0.15 | 35 | ||||

| 0.16 | 34 | ||||

| 0.17 | 34 | ||||

| 0.18 | 33 | ||||

| 0.2 | 32 | 0.2 | 32 | ||

| 0.21 | 32 | ||||

| 0.23 | 31 | ||||

| 0.25 | 30 | 0.25 | 30 | 0.25 | 30 |

| 0.27 | 29 | ||||

| 0.28 | 29 | ||||

| 0.29 | 29 | ||||

| 0.3 | 29 | 0.3 | 29 | ||

| 0.32 | 28 | 0.32 | 28 | 0.32 | 28 |

| 0.35 | 28 | ||||

| 0.37 | 27 | 0.37 | 27 | ||

| 0.38 | 27 | ||||

| 0.4 | 26 | 0.4 | 26 | 0.4 | 26 |

| 0.42 | 26 | ||||

| 0.45 | 25 | 0.44 | 25 | ||

| 0.5 | 24 | 0.5 | 24 | 0.5 | 24 |

| 0.54 | 23 | ||||

| 0.6 | 22 | 0.6 | 22 | ||

| 0.64 | 22 | 0.64 | 22 | ||

| 0.7 | 21 | 0.72 | 21 | ||

| 0.8 | 20 | 0.81 | 20 | 0.8 | 20 |

| 0.9 | 19 | 0.9 | 19 | 0.9 | 19 |

| 1 | 18 | ||||

| 1.15 | 17 |

Hot Cutting Wire

One of the most notable properties of nickel chrome is that it has high resistance, which causes it to heat up when an electrical current is applied to it. This means that nickel chrome wires are commonly used as hot cutting wire. This is perfect for using for foam cutting equipment, the wire heats up to hundreds of degrees temperature within seconds. With the strength of the wire and the high temperature, it enables it to cut through foam as well as power many electrical appliances.

How To Control The Temperature Of Nichrome Wire

An electric circuit is controlled by a resistance wire. Having a high resistivity allows you to use a shorter wire. A resistor should be selected based on its temperature coefficient of resistivity and corrosion resistance when stability is of primary importance. A high resistance to heat and oxidation are important characteristics when using this material for heating elements for electric heaters and toasters.

Resistivity Of Nichrome Wire

It’s also common for resistance wires to be insulated by ceramic powder which is encased in tubes of another alloy. Heating elements of this type are used in household appliances such as electric ovens, specialised cooktops and water heaters to DIY and craft projects.

As the most common resistance wire for heating purposes, nickel chromium is also a non-magnetic alloy. In order to use it as a heating element, it is usually wound into coils. As nichrome wire does not bond well with tin-based electrical solder, other methods need to be used for connections to electrical power, such as crimp connectors and screw terminals.

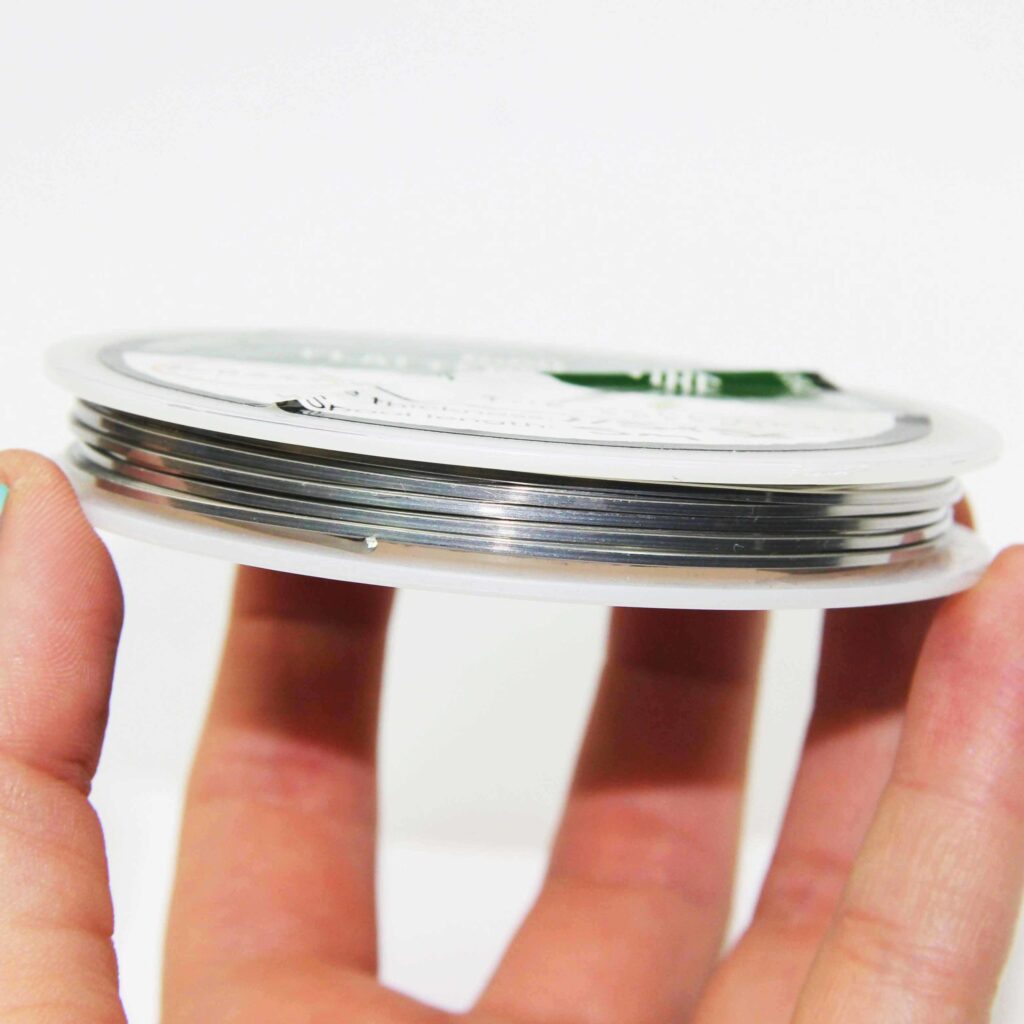

We offer also a massive range of stainless steel wire and nichrome wire through our store. Choose the wire that you want to work with and we’ll get spooling.

If you’re interested in learning more about wire, check out our other blog on Everything You Need to Know About Wires.

We are also proud to supply this product on our highly popular eBay store, check us out there too.

Thank you for checking out our site.

- MULTIBUY SAVINGS – ORDER 5 FOR 20% OFF

- FREE UK Delivery For All Orders Over £25

- Immediate Express Dispatch From Stock

- Orders Fulfilled From Warrington, UK

- Tracked Delivery with Order Updates

- 30-Day Unused Returns Accepted

Nichrome Wire Safety: Top Tips for Working Safely

Best Wire for Electronics Projects

Is Ni80 Wire Suitable for DIY Heating Elements

Wire Grades Explained

How Wire Diameter Affects Strength and Flexibility

How to Cut and Shape Wire for Custom Applications

Can Wire Be Used in 3D Printing?

How Wire Composition Affects Conductivity