Description

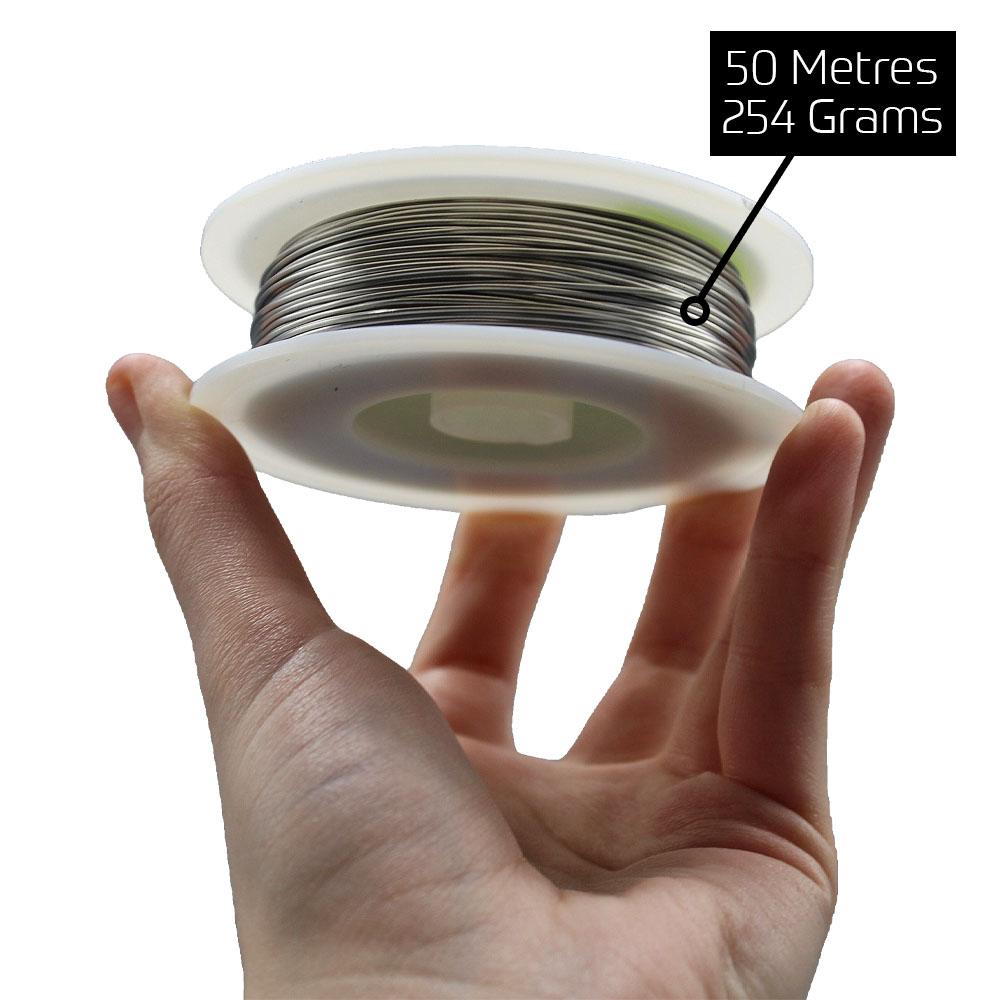

20 AWG Stainless Steel Wire

The Crazy Wire Company are long established as Europe’s preferred suppliers of top quality stainless steel 20 AWG SS316L wire. We have enormous stock levels at all times, as we use this wire to weave our marine grade woven mesh products.

The 20 awg SS316L marine grade stainless steel wire, with its nominal diameter of 0.8mm, substantiates a reliable solution for numerous applications across a wide array of industries, thanks to its characteristic amalgamation of durability, corrosion resistance, and excellent formability. The 20 awg wire is particularly robust in harsh environments, ensuring sustained performance in marine applications that require resistance to saltwater corrosion. Among beaders and jewelry makers, the wire’s tensile strength and anticorrosive properties make it a preferred choice for crafting pieces that will last.

Artists and DIY enthusiasts can manipulate it into intricate designs without sacrificing structural integrity. This wire is also often used in various industrial settings, such as springs, wire mesh, and a wide variety of fasteners, as well as for reinforced concrete in the construction sector, which ensures longevity and stability. The stainless steel wire, 20 gauge, stands as a versatile and steadfast choice for both professionals and hobbyists. It bridges a variety of applications by providing a consistent combination of durability, environmental resistance, and usability, making it appealing to a wide range of users.

Specification of Wire:

- Diameter – 0.8mm (800 Micron – 20 AWG)

- ohms/m – 1.41

We also offer this grade as ribbon wire and flat wire too if required.

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

Not only do we offer 304 grade stainless steel wire, but we also stock huge levels of SS316, SS430 (magnetic) and SS317L.

We also offer stainless steel in ribbon and flat wire options.

The choice is virtually endless!

FAQs About This Wire

What Are The Safety Precautions For Handling SS316L Stainless Wire?

Handling SS316L stainless steel wire, necessitates adherence to certain safety precautions to protect individuals from potential hazards and ensure a secure working environment:

General Handling:

- Wear Protective Gear:

- Use gloves to prevent cuts or injuries from the wire edges.

- Wear safety glasses to protect eyes from potential wire snaps or debris.

- Tool Safety:

- Utilize appropriate tools (wire cutters, pliers, etc.) and ensure they are in good working condition.

- Ensure familiarity with tool operation to avoid mishaps.

- Material Stability:

- Securely store rolls or coils to prevent unraveling and maintain a tidy workspace.

During Cutting and Coiling:

- Cutting Caution:

- Be cautious when cutting wire, as the released tension might cause it to recoil or snap back.

- Secure Workpiece:

- Ensure the wire being worked on is securely fastened or stabilised.

- Avoid Overextension:

- Refrain from over-stretching or applying excessive tension to prevent unexpected release.

Welding or Joining:

- Welding Safety:

- Use welding helmets, gloves, and aprons when welding wire to shield from sparks or molten metal.

- Ventilation:

- Ensure proper ventilation to avoid inhaling any fumes produced during welding or soldering.

Storage and Disposal:

- Proper Storage:

- Store wire away from walkways or areas with foot traffic to avoid tripping hazards.

- Disposal:

- Dispose of or recycle off-cuts and wire scraps in an appropriate manner to prevent injury.

Ergonomics:

- Correct Posture:

- Maintain an ergonomic posture when working to prevent muscle strain.

- Take Breaks:

- Regularly pause during repetitive tasks to minimise physical strain and promote focus.

How Does The SS316L 20 AWG Wire Perform In High Humidity Environments?

SS316L 20 AWG wire is particularly known for its corrosion-resistant properties, which make it ideal for high humidity environments. Marine grade stainless steels, like SS316L, are enriched with molybdenum, which significantly enhances their corrosion resistance. Even in environments with high humidity levels, it retains its structural integrity and aesthetic appearance without being subjected to rusting or oxidation processes common to less resistant metals. In maritime applications, coastal settings, or any scenario involving persistent moisture, the 20 AWG wire remains resilient and functional.

Aside from resisting degradation, it provides a reliable solution for structures, creations, and applications that require a material that can withstand such conditions without deteriorating. The durability and resilience of SS316L 20 AWG wire makes it an ideal choice for professionals and enthusiasts seeking long-lasting and dependable materials. Consequently, whether it is used in craftsmanship, industrial manufacturing, or outdoor settings, it also safeguards investments and ensures longevity for projects in moist environments.

Can SS316L 20 AWG Wire Be Painted or Coated?

Yes, SS316L 20 AWG wire can indeed be painted or coated, although the inherent corrosion-resistant properties of stainless steel often render additional protective coatings optional in various applications. However, applying a paint or coating can be pursued for aesthetic purposes, additional environmental protection, or to meet specific application requirements. Before painting or applying a coating, the wire should be thoroughly cleaned to remove any oils, residues, or contaminants to ensure optimal adhesion. Priming the stainless steel wire with an appropriate primer that adheres to metal surfaces is crucial to enhance the paint’s durability and longevity. Epoxy coatings, powder coatings, or specific metal paints are often preferred for their durability and adherence to metal surfaces like stainless steel.

Additionally, for applications demanding enhanced resistance against harsh chemicals, abrasion, or extreme conditions, specialised coatings, such as PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition) coatings, can be applied to the SS316L wire. In scenarios where electrical conductivity needs to be maintained, it’s pivotal to select a coating that doesn’t significantly impede the wire’s electrical properties. Therefore, while SS316L 20 AWG wire can be painted or coated, the selection of appropriate preparation procedures, paints, and coatings is vital to ensure the desired performance, aesthetics, and functionality in various applications.

The Crazy Wire Company is a leading UK based supplier of nichrome, FeCrAl, and stainless steel wires. We specialise in rapid delivery to any location around the country. Our factory is located in Warrington, which is the historic home of the UK’s wire industry.

Check out our blog ‘What You Need To Know About: Stainless Steel Wires’ for more information on resistance wire in general. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

Reviews

There are no reviews yet.