This guide on stainless steel wires is part of our series to outline everything that you need to know about our products. We hope that you find it helpful and that it answers any questions that you may have.

Bare stainless steel wires are wires that are made from stainless steel without any coating or insulation. They are commonly used in a variety of applications such as welding, fencing, and wire mesh manufacturing.

Stainless steel is a popular material for these wires because it is durable, corrosion-resistant, and can withstand high temperatures. It is also non-reactive with other materials, making it a safe and reliable option for many industrial and commercial applications.

This should answer some questions that you may have.

Let’s jump into it…

What Types Of Stainless Wire Are Available?

The types of stainless steel wire that we stock are as follows:

- 304: This is an austenitic stainless steel wire with good corrosion resistance and excellent strength.

- 316: This wire is a high-quality, corrosion-resistant wire that is often used in marine environments and other applications where resistance to corrosion and oxidation is essential.

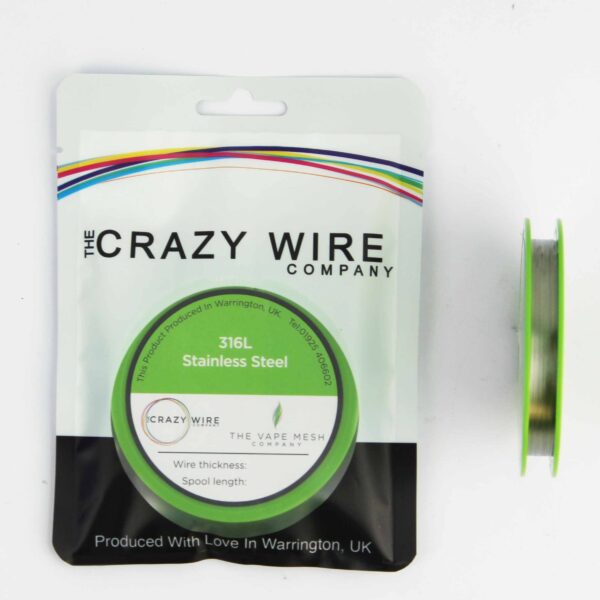

- 316L: This is a low-carbon version of 316 stainless steel wire that provides improved resistance to corrosion and high-temperature oxidation.

- 321: This is a type of austenitic stainless steel wire that contains titanium, which provides improved resistance to intergranular corrosion.

- 430: This is a ferritic stainless steel wire that offers good resistance to corrosion and is often used for applications such as weaving or knitting mesh.

- 904L: This is a high-performance austenitic stainless steel wire that provides excellent corrosion resistance, especially in harsh environments.

Let’s go through each individually…

304 Stainless Steel

Historically, 304 grade wire has proven to be a versatile and widely used type of wire that offers excellent corrosion resistance, high strength, and good formability, making it a popular choice for a variety of industrial and commercial applications.

304 stainless steel is a popular austenitic stainless steel. It is known for its excellent corrosion resistance, high ductility, good weldability, and high-temperature strength.

It contains high levels of chromium and nickel, which give it its corrosion resistance properties, and it can also be easily formed and fabricated into a range of different shapes and sizes.

In addition, 304 stainless steel is non-magnetic and has good thermal conductivity, making it a suitable material for use in a variety of industries, such as food processing, chemical and petrochemical processing, and medical equipment manufacturing.

316 Stainless Steel

316 stainless steel wire is a high-quality, corrosion-resistant wire that contains molybdenum, which provides additional resistance to corrosion and pitting in harsh environments such as marine and chemical processing applications.

It offers excellent strength, ductility, and weldability, making it a popular choice for many industrial and commercial applications that require durability and resistance to corrosion, including wire mesh manufacturing, welding, and construction.

316 wire is also non-magnetic and has good high-temperature resistance, which makes it suitable for use in applications that require high strength and reliability under extreme conditions.

It has a higher level of corrosion resistance compared to 304 stainless steel, and it is often used in harsh environments such as marine and chemical processing applications.

316 also has excellent resistance to pitting and crevice corrosion, making it a popular choice for applications where corrosion resistance is critical.

In addition, 316 stainless steel is non-magnetic, has good high-temperature resistance, and can be easily formed and fabricated into a range of different shapes and sizes, making it a versatile material for a variety of industrial and commercial applications.

921 Stainless Steel

921 grade stainless steel wire is a precipitation-hardening stainless steel that is often used in applications that require high strength, toughness, and corrosion resistance.

It contains high levels of chromium, nickel, and copper, which provide its excellent corrosion resistance properties, and it can be heat-treated to achieve high levels of strength and hardness.

921 grade stainless steel wire is often used in applications such as springs, fasteners, and other high-stress components, and it can also be used in marine and other harsh environments where resistance to corrosion is important.

However, due to its high copper content, 921 grade stainless steel may not be suitable for certain applications where electrical conductivity is a concern.

430 Stainless Steel

430 stainless steel wire is a ferritic stainless steel wire that is known for its excellent corrosion resistance, good formability, and high-temperature oxidation resistance.

It contains high levels of chromium, which provides its corrosion resistance properties, and it is often used in applications such as weaving or knitting mesh, welding, and other industrial and commercial applications.

430 stainless steel wire is also non-hardenable by heat treatment, which limits its use in high-stress applications. However, it is often used in applications where corrosion resistance is more important than strength, such as decorative trims or indoor architectural applications.

Most importantly, bare 430 stainless steel wire is magnetic, which makes it suitable for use in applications that require magnetic properties, such as magnetic cores or electrical components.

What Are The Most Common Uses?

These wires have a wide range of applications in various industries due to their excellent strength, durability, and resistance to corrosion. Some of the most common use include:

- Welding: It is often used in welding applications due to their high strength and corrosion resistance. They can be used to weld different metals and are commonly used in the automotive, aerospace, and construction industries.

- Wire mesh manufacturing: Our wires are used to manufacture various types of wire mesh, including woven wire mesh and welded wire mesh. These meshes are used in a wide range of applications, including filtration, screening, and fencing.

- Springs and fasteners: Stainless wires are often used to make springs and fasteners due to their high strength and corrosion resistance. They are commonly used in the automotive, aerospace, and medical industries.

- Jewellery: They are used in the production of jewellery due to their non-reactivity and durability. They are commonly used to make chains, clasps, and findings.

- Electrical and electronic components: They are used in the production of various electrical and electronic components due to their high electrical conductivity and resistance to corrosion. They are commonly used in wiring, connectors, and antennas.

- Medical equipment: Our wires are used in the production of various medical equipment, including surgical instruments and implantable medical devices, due to their non-reactivity and biocompatibility.

Will It Rust?

Stainless steel wires are resistant to rust, but this depends on the specific type of stainless steel and the environment in which the wire is used. Stainless steel wires contain a minimum of 10.5% chromium, which reacts with oxygen in the air to form a protective layer of chromium oxide on the surface of the wire. This layer is passive and prevents further oxidation and corrosion of the underlying metal.

However, if the surface of the wire is damaged or contaminated by other metals or chemicals, the passive layer can be compromised, leading to rust and corrosion. In addition, exposure to certain environments, such as marine or high-humidity environments, can also cause rust and corrosion over time.

To prevent rust and corrosion, it’s important to choose the right type of stainless steel wire for the application and to properly maintain and care for the wire. Regular cleaning, proper storage, and avoiding exposure to harsh chemicals or environments can help prolong the life of stainless steel wires and prevent rust and corrosion.

Are There Downsides To Using Stainless Steel Wire?

- Cost: It can be more expensive than other materials due to its high-quality and corrosion resistance properties. Our wire is not expensive because we stock so much for producing wire mesh materials however.

- Brittleness: Some grades can be more brittle than other materials. This can make them prone to breaking or cracking under certain conditions.

- Difficulty of Machining: It can be more difficult to machine than other materials due to its high strength and hardness.

- Low thermal conductivity: Stainless steel has a relatively low thermal conductivity, which means that it may not be the best choice for certain high-temperature applications.

We think that it pretty much everything that you might need to know about this use for our wire. We offer also a massive range of stainless steel wire and other nickel materials through our store. Choose the wire that you want to work with and we’ll get spooling.

If you’re interesting in learning more about wire, check out our other blog on Everything You Need to Know About Wires.

We are also proud to supply this product on our highly popular eBay store, check us out there too.

Thank you for checking out our site.