Description

0.84mm Resistance Ni200 Nickel Wire

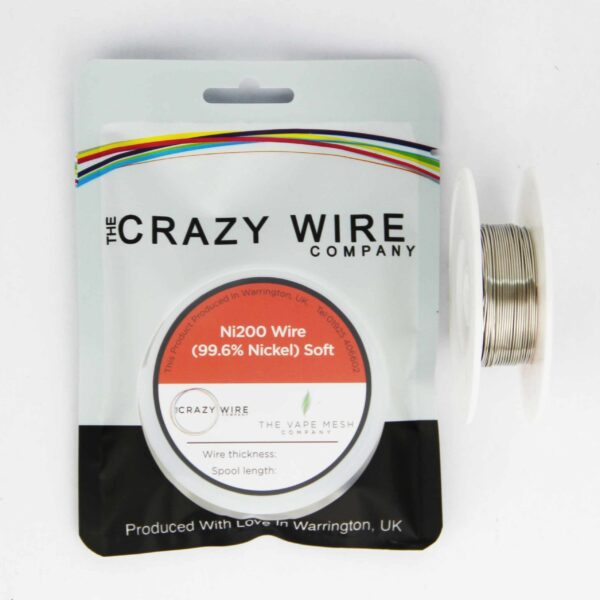

The Crazy Wire Company are well known as suppliers of top quality Ni200 nickel wire. We have enormous stock levels at all times, as we use this wire to weave our high specification woven mesh products. Our brilliant staff are experts in producing our spools of round wire on our 6 rapid action winding machines. All spools are produced to carry a little extra length to make up for any waste when handling the product.

The 0.84mm soft Ni200 wire, composed of tempered 99.6% nickel, stands out in the electrical and electronics domain owing to its pronounced thermal and electrical conductive properties. NI200 wire is widely used in various industrial sectors because of its exceptional resistance to corrosion and malleability, making it an ideal choice for a variety of applications, particularly in environments where maintaining purity is crucial. With its low electrical resistance and stability across a wide range of temperatures, it is widely used to create temperature control devices and systems. In 3D printer beds, electrical appliances, ceramic pads, and other electronic applications where maintaining a consistent and regulated temperature is crucial, it is particularly useful.

Ni200 is used in the aerospace and automotive industries to manufacture temperature sensors and controllers that are reliable and stable under variable thermal conditions. Moreover, it is used in heat sealing and heat forming processes to ensure durability and consistent performance of automated systems in the realm of robotics and machinery. Its corrosion resistance makes it an ideal material for medical devices and implants, preventing degradation and ensuring biocompatibility. Due to its stable resistive properties, it is also ideal for crafting precision resistors and potentiometers in various electronic components. High-precision temperature control systems are used in laboratories to conduct sensitive experiments and processes. The 0.84mm soft Ni200 wire offers reliability, precision control, and robustness, while successfully meeting the stringent demands of diverse industrial applications.

Key product details:

- Diameter – 0.84mm (840 Micron – 20 AWG)

- Ohms/m – 0.17

- Technical Specification:

- Ni+Co – Max 99.6% / Min 99.0%

- Fe – 0.4%

- C – 0.15%

- Mn – 0.35%

- Si – 0.35%

- Cu – 0.25%

- S – 0.01%

- Density – 8.89 g/cm3

- Melting Point – 1435 – 1446 oC

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

Not only do we offer Ni200 wire, but we also stock huge levels of Ni60, Ni80 and Ni90.

We also offer stainless steel in ribbon and flat wire options.

The choice is virtually endless!

FAQs About This Wire

What Are The Safety Precautions For Handling Ni200 Wire?

- Wear Protective Gear:

- Always use gloves to prevent any skin irritation, especially for those with nickel allergies.

- Use safety goggles to shield eyes from potential wire snap-backs or any fragmented pieces during handling or cutting.

- Storage and Handling:

- Store ni200 wire rolls or coils in a dry and cool environment to prevent any oxidative or corrosive damage.

- Ensure the wire is unwound carefully to avoid kinking or damaging its structure.

- Cutting and Bending:

- Use appropriate cutting tools to prevent splintering or fraying of the wire.

- When bending or shaping ni200 wire, do so gently and gradually to avoid creating weak points or breaks.

- Avoiding Contamination:

- Keep the wire away from contaminants that could potentially adhere to its surface and affect its performance.

- Ensure that hands are clean or use clean gloves to avoid transferring oils or other substances to the wire.

- Temperature Management:

- Be mindful of the wire’s resistive heating and ensure it’s used within safe temperature parameters.

- Ensure any heat treatment is done in a controlled environment to prevent overheating and degradation of the wire.

- Electrical Safety:

- When used in electrical applications, ensure all power sources are switched off before installing or adjusting the ni200 wire to prevent shocks or shorts.

- Validate all electrical connections and installations to avoid potential failures or fire hazards.

- Chemical Exposure:

- Limit the wire’s exposure to harsh chemicals or environments that might compromise its integrity.

- Utilize appropriate coatings or shieldings if used in a chemically aggressive environment.

- Compliance:

- Ensure all handling and utilization of ni200 wire comply with industry standards and guidelines.

- Disposal:

- Dispose of any waste or off-cuts safely and in accordance with local regulations to prevent environmental impact or harm.

- Documentation:

- Maintain thorough documentation of handling, usage, and maintenance for traceability and quality control purposes.

Is Nichrome Ni200 Wire Corrosion-Resistant?

There is a difference between Ni200 and nichrome, which should not be confused. The corrosion resistance of Ni200 wire, composed of approximately 99.6% nickel, is particularly notable in certain chemical environments. As a result of its inherent resistance to corrosion in oxidising, neutral, and reducing environments, it can be applied to a variety of applications where maintaining material purity and stability is critical. Ni200’s excellent corrosion resistance is ideal for applications that require exposure to corrosive elements, such as manufacturing processes that involve caustic alkalis. In terms of nichrome, an alloy of nickel, chromium, and often iron, it has its own set of properties and is widely used because of its resistance to oxidation and stable resistive properties at high temperatures.

What Are The Thermal Properties Of Ni200 Wire?

Ni200 wire, composed predominantly of nickel (at least 99.6%), is renowned for its distinguished thermal properties, which have enabled its widespread application in various industries. Among its notable thermal characteristics is its high electrical conductivity, which is complemented by a relatively low thermal expansion coefficient, making it stable and reliable in variable thermal environments. Moreover, Ni200 possesses excellent resistance to thermal cycling, ensuring it maintains structural integrity and functionality through fluctuations in temperature. It also exhibits a high melting point of approximately 1455 degrees Celsius (2651 degrees Fahrenheit), providing resilience in high-temperature applications and environments.

Its impressive ductility at various temperature ranges and resistance to creep at high temperatures further cement its utility in applications that necessitate consistent performance amidst variable thermal conditions. In temperature-sensitive applications, such as in temperature sensors and control devices, the precise and reliable resistance-temperature relationship of Ni200 is leveraged to maintain and monitor accurate temperature regulation. The aforementioned thermal properties not only underscore the versatility of Ni200 wire in diverse applications but also attest to its reliability in ensuring optimal performance in tasks that demand precise thermal management and stability.

The Crazy Wire Company is a leading UK based supplier of nichrome, FeCrAl, and stainless steel wires. We specialise in rapid delivery to any location around the country. Our factory is located in Warrington, which is the historic home of the UK’s wire industry.

Check out our blog ‘What You Need To Know About: Stainless Steel Wires’ for more information on resistance wire in general. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

Reviews

There are no reviews yet.