Description

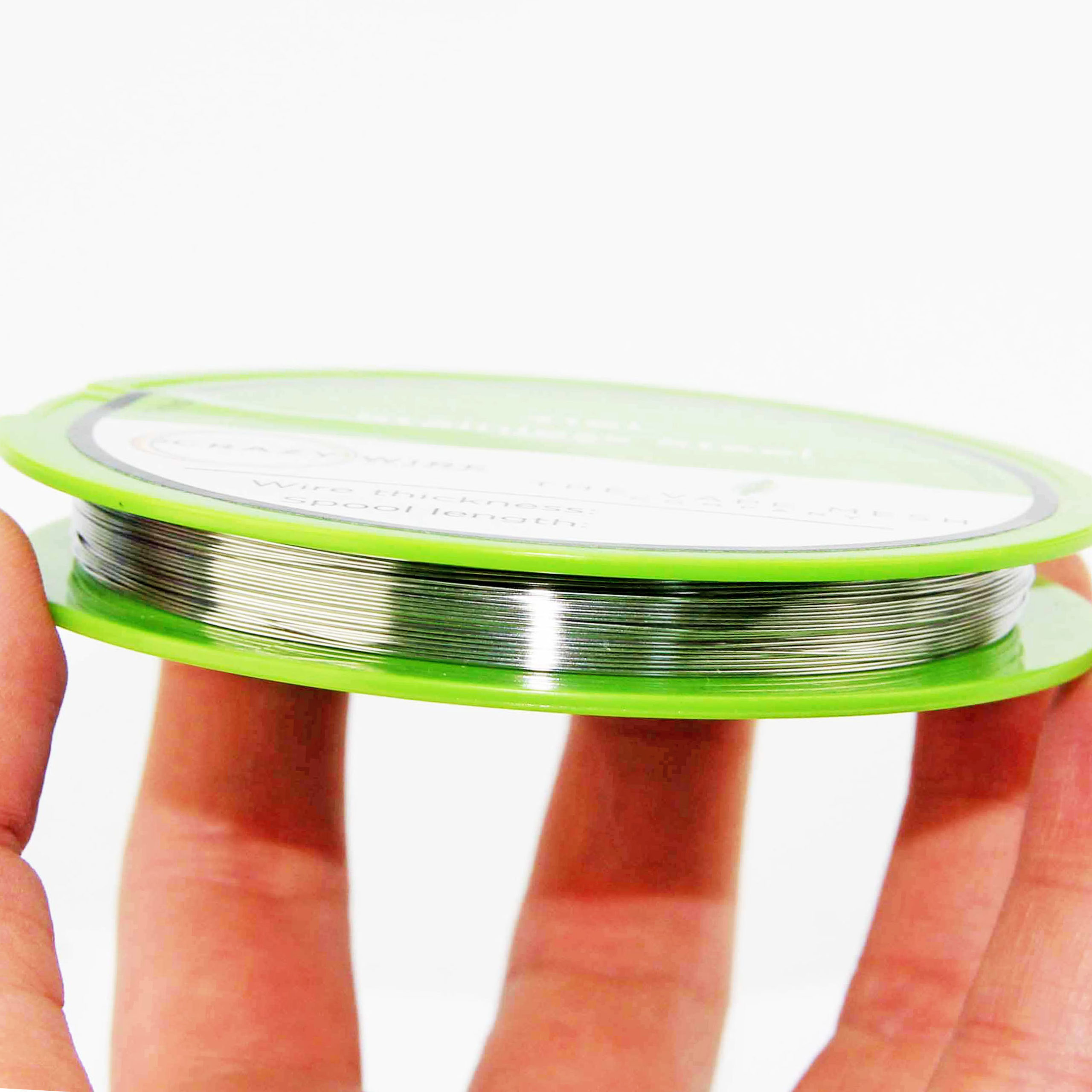

0.34mm 316L Stainless Steel Wires

The Crazy Wire Company are long established as Europe’s preferred suppliers of top quality stainless steel wires. We have enormous stock levels at all times, as we use this wire to weave our marine grade woven mesh products.

The 0.34mm (27 AWG) ss316L marine grade stainless steel wires provide a versatile and reliable solution suitable for various applications in challenging environments. This high-quality stainless steel wire is manufactured with precision. It’s resistant to corrosion, even in marine conditions where saltwater and aggressive weather elements are present. Wires like these are used extensively for rigging, securing cargo, and crafting marine accessories, ensuring durability and reducing maintenance costs. When it comes to electronics, they play an important role in creating robust connections and components, especially when resistance to environmental factors is a concern. A medical device or surgical instrument made from stainless steel 316L wires is both biocompatible and corrosion-resistant, ensuring both functionality and sterility. These wires provide structural and aesthetic support for construction and architecture structures that require slender yet sturdy components. During the lifetime of a vehicle, these wires are used to manufacture parts that are not only strong but also resistant to harsh environmental conditions. Furthermore, they allow artists and designers to create intricate, durable pieces without worrying about deterioration.

Specification of Wire:

- Diameter – 0.34mm (340 Micron – 27 AWG)

- ohms/m – 7.82

We also offer this grade as ribbon wire and flat wire too if required.

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

Not only do we offer 304 grade stainless steel wire, but we also stock huge levels of SS316, SS430 (magnetic) and SS317L.

We also offer stainless steel in ribbon and flat wire options.

The choice is virtually endless!

FAQs About This Wire

Can SS316L Stainless Steel Wires Be Colored Or Coated For Aesthetic Purposes?

Yes, SS316L stainless steel wires can be colored or coated for aesthetic or functional purposes, using various techniques to ensure adherence to the metal while retaining its original properties. In addition to providing an attractive appearance, coatings can provide additional protection against certain environmental factors. Stainless steel can be colored using PVD (Physical Vapor Deposition) using a variety of hues while maintaining its corrosion and tarnish resistance.

Powder coating can also be applied to the stainless steel wires to provide a vibrant and durable finish as well as an additional layer of protection. The process selected should not compromise the integrity, flexibility, or corrosion-resistance properties of SS316L stainless steel wires. To ensure that the coating or color chosen is aligned with the intended use and meets all applicable standards and regulations, it is crucial to consult with a specialist or manufacturer when considering coatings or colors for specific applications. This ensures both aesthetic and functional longevity of the wire in its intended environment.

How Do SS316L Stainless Steel Wires React To Prolonged Sunlight Exposure?

SS316L stainless steel wires exhibit commendable resistance and stability under prolonged sunlight exposure, largely maintaining their integrity and functionality over time. The chromium content within the SS316L grade forms an oxide layer on the wire’s surface, which actively resists corrosion and prevents substantial damage from various environmental exposures, including sunlight. It doesn’t degrade or become brittle when exposed to UV rays, which is a vital characteristic for outdoor applications. However, while the structural properties remain steadfast, slight surface changes may occur over an extended period of direct sunlight exposure, such as minimal color alteration or the development of a thin, protective oxide layer.

It’s also worth noting that in extremely harsh conditions involving consistent, strong sunlight and other exacerbating environmental factors like high salinity or industrial emissions, even the robust SS316L stainless steel may experience a gradual, albeit slow, onset of corrosion or material fatigue over an extended timeframe. It is crucial to regularly inspect the wires in such settings and ensure that they remain in optimal condition, safeguarding against unexpected failures and maintaining the reliability of applications dependent on their stability. For specific applications where UV stability is crucial, it may be worthwhile to explore additional surface treatments or coatings. This can further enhance the wire’s resistance to prolonged sunlight exposure.

What Is The Life Expectancy Of SS316L Stainless Steel Wires In Harsh Conditions?

The life expectancy of SS316L stainless steel wires, especially in harsh conditions, can be significantly robust due to their intrinsic corrosion-resistant properties. SS316L grade is recognised for its lower carbon content and addition of molybdenum. It provides enhanced resistance to pitting from chloride solutions, a common issue in marine and chemical environments. Nevertheless, the actual longevity of these wires in severe conditions depends on multiple factors, including the specific type of environment (marine, industrial, acidic, etc.), the mechanical stress applied to the wire, and the maintenance practices followed.

In general, and under normal conditions, SS316L can offer several decades of service life, exhibiting minimal degradation over time. However, in exceptionally adverse circumstances such as continuous exposure to highly corrosive chemicals, extreme temperatures, or perpetual mechanical stress, the life expectancy might be curtailed, necessitating more frequent replacements or upgrades. Implementing regular maintenance checks and adhering to best practices in installation and use will be pivotal in optimising the life span of SS316L stainless steel wires in any application, even under the toughest conditions. Moreover, it’s always beneficial to consult with a corrosion specialist or an engineer when deploying stainless steel wires in notably harsh environments to define maintenance schedules and predict possible life expectancy more accurately based on specific use-case scenarios.

The Crazy Wire Company is a leading UK based supplier of nichrome, FeCrAl, and stainless steel wires. We specialise in rapid delivery to any location around the country. Our factory is located in Warrington, which is the historic home of the UK’s wire industry.

Check out our blog ‘What You Need To Know About: Stainless Steel Wires’ for more information on resistance wire in general. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

Reviews

There are no reviews yet.