Marine grade stainless steel wire is a crucial component in many maritime applications due to its exceptional resistance to corrosion, strength, and durability. However, with increasing emphasis on sustainability and environmental responsibility, can marine grade stainless steel wire be recycled? The answer is a resounding yes. In this article, we will discuss how marine grade stainless steel wire can be recycled, as well as its benefits, challenges, and broader implications.

Understanding Marine Grade Stainless Steel Wire

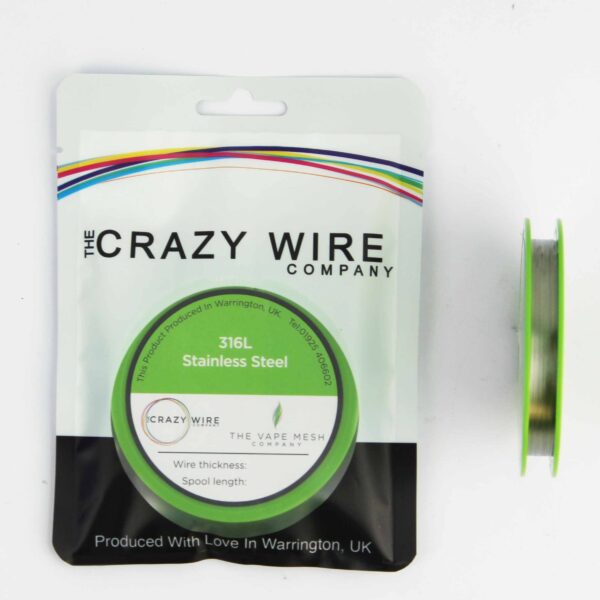

Before diving into the recycling process, it’s essential to understand what marine stainless steel wire is and why it is so valued in maritime environments. Marine grade stainless steel typically refers to alloys such as 316 and 316L. These contain high levels of chromium, nickel, and molybdenum. These elements enhance the alloy’s resistance to pitting and corrosion, making it ideal for use in saltwater and other harsh environments.

Marine grade stainless steel wire is used in various applications, including rigging, lifelines, guardrails, and anchoring systems, where exposure to corrosive elements is a constant threat. Its ability to withstand these conditions without significant degradation ensures safety and longevity, which are paramount in maritime operations.

The Recycling Process of Marine Grade Stainless Steel Wire

Recycling marine grade stainless steel wire involves several stages, each crucial to transforming the used material into a form that can be reused. The recycling process can be broken down into the following steps:

Collection and Sorting: The first step in recycling marine grade stainless steel wire is the collection of scrap material. This scrap can come from decommissioned ships, old equipment, and other maritime sources. The collected material is then sorted to separate stainless steel from other metals and contaminants.

Shredding and Melting: Once sorted, the stainless steel wire is shredded into smaller pieces to facilitate easier handling and melting. The shredded material is then melted in an electric arc furnace (EAF). During this process, the high temperatures break down the stainless steel into a molten state, allowing impurities to be removed.

Refining and Alloying: After melting, the molten stainless steel undergoes refining to remove any remaining impurities. This step is crucial to ensure the recycled stainless steel meets the desired quality and composition standards. Alloying elements like chromium, nickel, and molybdenum may be added to restore the material to its original specifications.

Casting and Forming: The refined molten stainless steel is then cast into various shapes, such as billets or slabs, which can be further processed into wires, sheets, and other forms. For marine grade stainless steel wire, the material is typically drawn through dies to achieve the desired diameter and tensile strength.

Finishing: The final step involves finishing processes such as annealing. This enhances the ductility and strength of the wire, and surface treatments to improve corrosion resistance. The finished product is then ready for reuse in new maritime applications.

Benefits of Recycling Marine Stainless Steel Wire

Recycling marine grade steel wire offers numerous benefits, both environmentally and economically. Here are some of the most significant advantages:

Resource Conservation: Recycling stainless steel conserves natural resources by reducing the need for mining and extracting raw materials. Chromium, nickel, and molybdenum are finite resources, and their extraction can have significant environmental impacts. Recycling helps to extend the life of these materials.

Energy Savings: The recycling process consumes significantly less energy compared to producing stainless steel from raw materials. Melting scrap stainless steel in an EAF uses about one-third of the energy required to produce new stainless steel from virgin ore. This reduction in energy consumption translates to lower greenhouse gas emissions and a smaller carbon footprint.

Waste Reduction: Recycling reduces the amount of waste sent to landfills. Stainless steel is a valuable material that can be recycled indefinitely without losing its properties. By recycling marine grade stainless steel wire, we minimize the environmental impact of waste disposal and promote a circular economy.

Economic Benefits: The recycling industry generates economic benefits by creating jobs and providing a supply of raw materials at a lower cost than new production. Recycled stainless steel is often less expensive than virgin material. This can reduce manufacturing costs for industries that rely on stainless steel.

Sustainability: By recycling marine grade stainless steel wire, industries can enhance their sustainability profiles. Sustainable practices are increasingly important to consumers, investors, and regulatory bodies. Recycling supports corporate social responsibility initiatives and helps companies meet sustainability goals.

Challenges in Recycling Marine Grade Steel Wire

Despite the clear benefits, recycling marine grade stainless steel wire presents several challenges that must be addressed to maximize its effectiveness:

Contamination: One of the primary challenges in recycling stainless steel is contamination. Marine environments expose stainless steel to various contaminants, including salt, organic matter, and other metals. Effective sorting and cleaning processes are necessary to ensure the recycled material is of high quality.

Separation of Alloys: Marine grade stainless steel must be carefully separated from other types of stainless steel and metals. Different alloys have specific compositions and properties, and mixing them can result in inferior products. Advanced sorting technologies, such as spectroscopy and magnetic separation, are required to achieve precise alloy separation.

Processing Costs: While recycling is generally more cost-effective than producing new stainless steel, the initial investment in recycling facilities and technologies can be high. Companies must weigh these costs against the long-term benefits of recycling.

Market Fluctuations: The market for recycled stainless steel can be volatile, influenced by factors such as demand, raw material prices, and regulatory changes. These fluctuations can impact the profitability and stability of recycling operations.

Public Awareness and Participation: Increasing public awareness and participation in recycling programs is crucial. Ensuring that industries and consumers properly dispose of stainless steel products for recycling can enhance the efficiency and effectiveness of recycling efforts.

The Future of Marine Grade Stainless Steel Wire Recycling

The future of marine grade stainless steel wire recycling is promising, with advancements in technology and increasing environmental awareness driving improvements in recycling processes. Here are some trends and developments that could shape the future of this industry:

Innovative Recycling Technologies: Advances in recycling technologies, such as improved sorting systems, more efficient melting processes, and better refining techniques, will enhance the quality and efficiency of recycled stainless steel. Innovations like laser-induced breakdown spectroscopy (LIBS) and robotic sorting systems can improve the accuracy of alloy separation.

Circular Economy Initiatives: The push towards a circular economy, where materials are reused and recycled to minimize waste, will encourage more industries to adopt recycling practices. Governments and organizations are likely to implement policies and incentives that promote recycling and sustainable manufacturing.

Collaboration Across Industries: Collaboration between maritime industries, recycling companies, and researchers can lead to the development of best practices and standards for recycling marine grade stainless steel wire. Sharing knowledge and resources can enhance the overall efficiency and effectiveness of recycling efforts.

Sustainable Product Design: Designing products with recycling in mind can facilitate easier disassembly and material recovery at the end of their life cycle. For marine stainless steel wire, this could involve using modular components and avoiding the use of hazardous materials that complicate recycling.

Global Recycling Networks: Establishing global recycling networks can help manage the supply and demand for recycled stainless steel more effectively. International cooperation can ensure that recycling facilities are accessible and that recycled materials are distributed efficiently.

Marine grade stainless steel wire plays a vital role in maritime applications due to its exceptional durability and resistance to corrosion. By recycling these materials, we save natural resources, reduce energy consumption, and benefit the environment and the economy at the same time. Despite challenges such as contamination and processing costs, advancements in recycling technologies and a growing emphasis on sustainability are making recycling processes more efficient and effective.

In order to create a more sustainable future, industries should embrace recycling practices and promote a circular economy. The recyclable nature and durability of marine grade steel wire illustrate the potential for materials to be reused and repurposed indefinitely, reducing environmental impacts and enhancing maritime resilience.

We offer also a massive range of stainless steel wire and nichrome wire through our store. Choose the wire that you want to work with and we’ll get spooling.

If you’re interested in learning more about wire, check out our other blog on Stainless Steel 304 vs 316 Wire.

We are also proud to supply this product on our highly popular eBay store, check us out there too.

Thank you for checking out our site.

Nichrome Wire Safety: Top Tips for Working Safely

Best Wire for Electronics Projects

Is Ni80 Wire Suitable for DIY Heating Elements

Wire Grades Explained

How Wire Diameter Affects Strength and Flexibility

How to Cut and Shape Wire for Custom Applications

Can Wire Be Used in 3D Printing?

How Wire Composition Affects Conductivity