Description

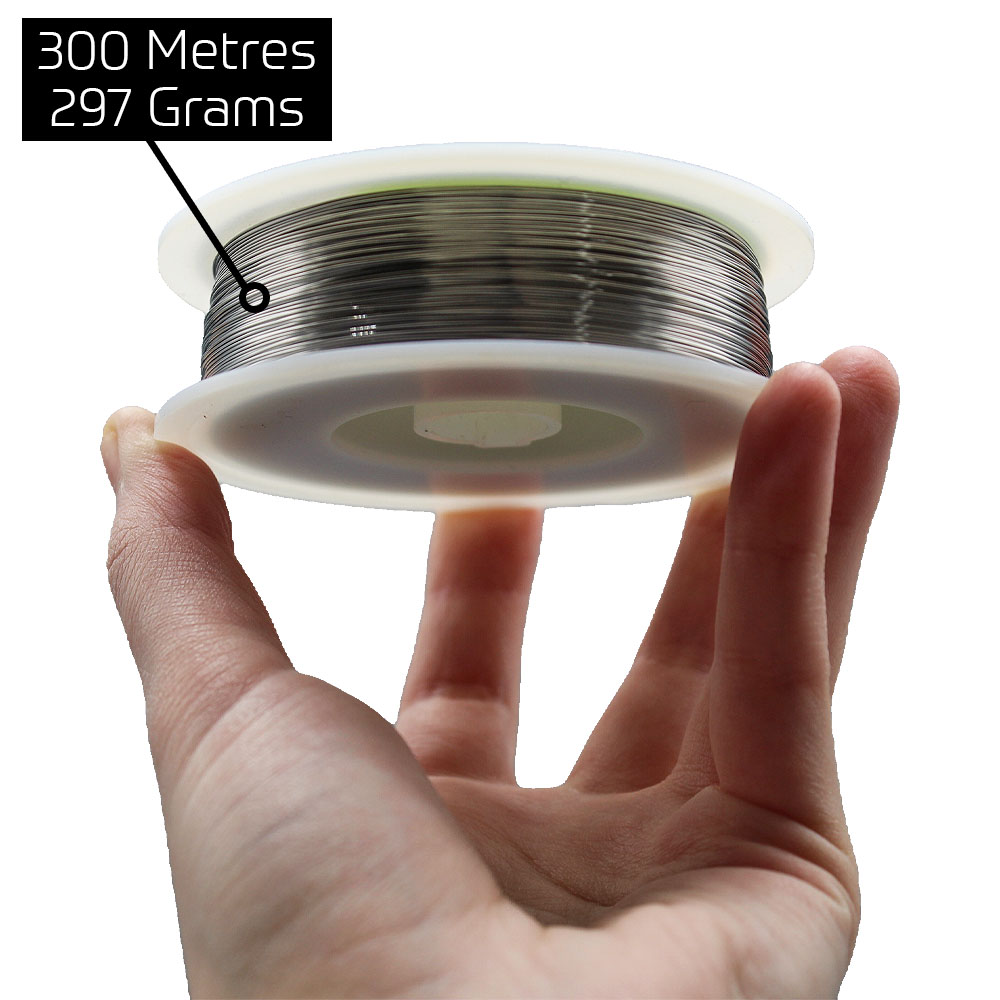

0.35mm Stainless Steel Metal Wires

The Crazy Wire Company are long established as Europe’s preferred suppliers of top quality stainless steel metal wires. We have enormous stock levels at all times, as we use this wire to weave our marine grade woven mesh products.

With their robust and versatile properties, 0.35mm (27 AWG) SS316L stainless steel metal wires are great for using across diverse industries. Metal wires made from the SS316L alloy are resistant to corrosion in various environments, whether you are exposing it to corrosive elements, high temperatures, or stringent sanitary conditions. Generally used in electrical applications, these metal wires offer durability and reliable conductivity. Its delicate diameter, combined with its innate strength, ensures a balance between aesthetic appeal and structural integrity in jewelry design. These metal wires are also used in construction applications like wire mesh or cable railing systems, providing a sleek, modern aesthetic without compromising strength or durability. SS316L is also known for its biocompatibility, facilitating its use as surgical instruments and implants in the medical field. A corrosion-resistant metal is the ideal choice for marine equipment and fixtures, since it ensures longevity and consistent performance in saline environments. Weldability and formability of metal wires further extend their versatility across fabrication endeavors. This supports both large-scale industrial operations and more precise, handcrafted products.

Specification of Wire:

- Diameter – 0.35mm (350 Micron – 27 AWG)

- ohms/m – 7.8

We also offer this grade as ribbon wire and flat wire too if required.

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

Not only do we offer 304 grade stainless steel wire, but we also stock huge levels of SS316, SS430 (magnetic) and SS317L.

We also offer stainless steel in ribbon and flat wire options.

The choice is virtually endless!

FAQs About This Wire

What Is The Electrical Conductivity Of The SS316L Metal Wires?

Compared to conductive metals such as copper and aluminum, SS316L stainless steel metal wires have a relatively low electrical conductivity. As a matter of fact, SS316L typically features an electrical conductivity of around 2.5 million Siemens per meter (2.5 MS/m). This is considerably lower than that of traditional electrical metals. The stainless steel alloys used to enhance corrosion resistance and mechanical properties, often at the expense of their electrical conductivity, are responsible for this characteristic. These alloys include elements such as chromium, nickel, and molybdenum. Although SS316L may not be the first choice for applications that require optimal electrical conductivity, its applications in electrical applications can still be found where corrosion resistance, strength, and biocompatibility are critical factors. Applications such as specific electronic components, sensors, and connectors, especially in harsh or corrosive environments where other more conductive materials might fail or corrode. SS316L metal wires have an incredibly detailed trade-off between conductivity and other mechanical and chemical properties. This allows them to fill a certain, albeit valuable, niche in certain electrical applications.

What Is The Maximum Load That The Metal Wires Can Safely Bear?

Determining the precise maximum load that the 0.35mm SS316L metal wires can safely bear necessitates consideration of multiple factors. This is not just including the material properties but also the configuration and application of the wire. Stainless steel 316L, or SS316L, is lauded for its excellent tensile strength and robustness amidst various environments. However, the actual load-bearing capacity of a wire of a specific diameter is influenced by its mechanical properties, design, and how it is deployed in a particular use-case. For a precise and safe calculation, it’s crucial to reference the specific tensile strength of SS316L. This is typically around 570 MPa, and apply it in the context of the wire’s cross-sectional area, adhering to appropriate safety factors and engineering guidelines.

Moreover, in real-world applications, factors such as the installation method, the angle of load application, vibration, corrosion, and temperature can also significantly impact the actual load-bearing capacity of the wire. Therefore, while a generic answer might provide a ballpark figure, it is emphatically recommended that engineers and professionals conduct a thorough analysis. They need to consider all pertinent variables to ascertain the safe working load of the SS316L metal wires in any specific application. Always prioritise safety and adhere to relevant standards and guidelines when deploying metal wires in load-bearing applications.

Are SS316L Metal Wires Compatible With Other Metals?

Yes, SS316L metal wires are generally compatible with various other metals. However, it is crucial to consider the specific context in terms of corrosion. This is especially in environments where the metals might be exposed to corrosive elements. SS316L is an austenitic stainless steel alloy known for its superior corrosion resistance. This makes it a safe choice in numerous applications alongside other metals. However, when metals with different electrode potentials are in electrical contact in a conductive, corrosive environment, galvanic corrosion can occur, potentially damaging one of the metals.

For instance, if SS316L stainless steel (which is relatively cathodic) is in contact with a more anodic metal like aluminum or carbon steel in a corrosive environment, the latter metals could corrode preferentially. Thus, when using SS316L metal wires with other metals, it’s advisable to consider factors like the specific application, environment, and potential for galvanic corrosion. Employing appropriate isolation techniques, like using non-conductive washers or coatings, can mitigate risks in situations where different metals need to be used together. Engaging a materials scientist or a corrosion engineer to analyse specific use-cases would further ensure the compatibility and longevity of the materials in the intended application. This will align with optimal performance and safety standards.

The Crazy Wire Company is a leading UK based supplier of nichrome, FeCrAl, and stainless steel wires. We specialise in rapid delivery to any location around the country. Our factory is located in Warrington, which is the historic home of the UK’s wire industry.

Check out our blog ‘What You Need To Know About: Stainless Steel Wires’ for more information on resistance wire in general. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

Reviews

There are no reviews yet.