Description

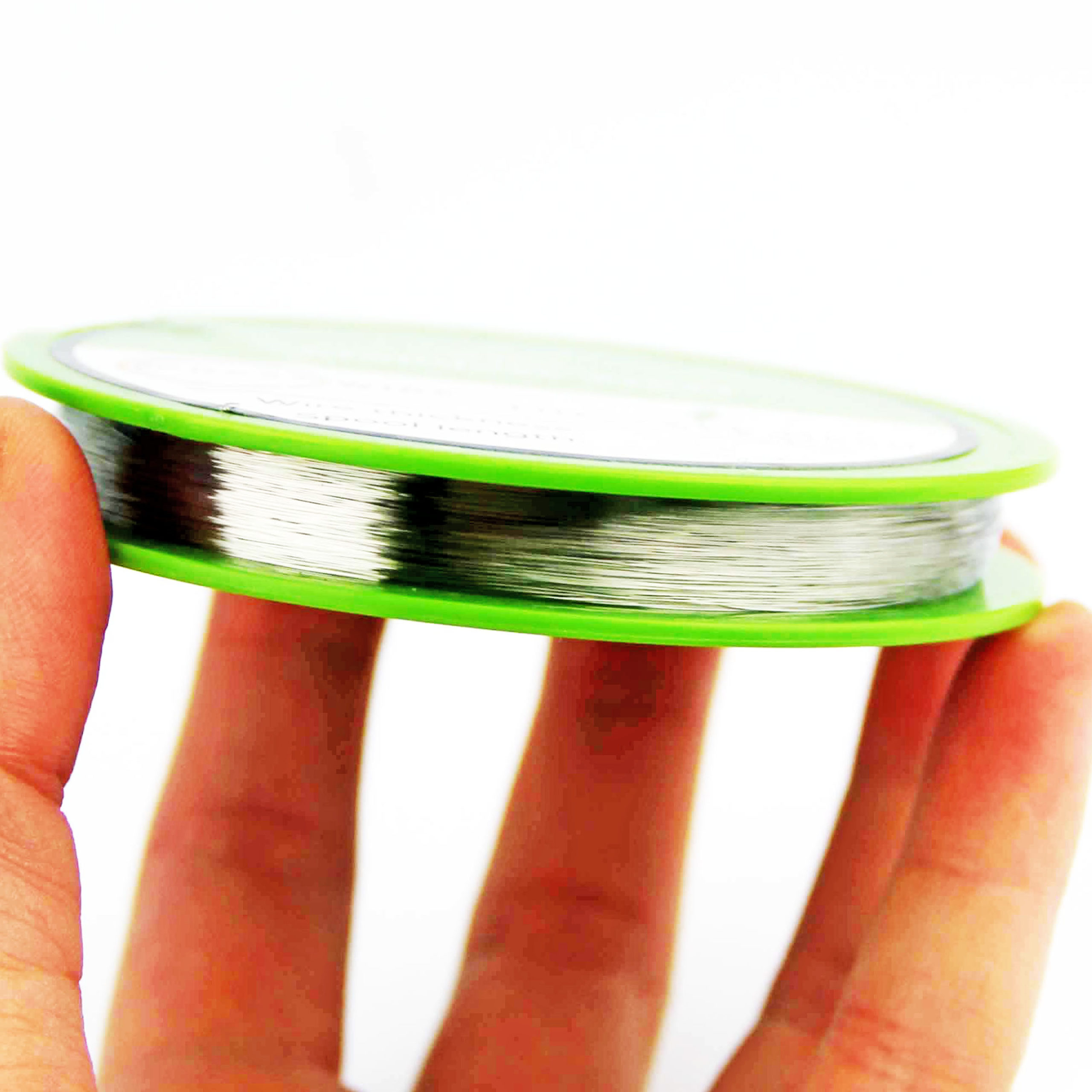

35 AWG Stainless Steel Wire

The Crazy Wire Company are long established as Europe’s preferred suppliers of top quality stainless steel 35 AWG SS316L wire. We have enormous stock levels at all times, as we use this wire to weave our marine grade woven mesh products.

The 35 awg SS316L marine grade stainless steel wire boasts a precise 0.14mm diameter. This ensures a fine balance between strength and lightweight properties. A material that is inherently corrosion-resistant, especially in saline or chloride environments, makes this wire suitable for a wide variety of industries, including but not limited to marine, aerospace, and construction. Specifically, it performs exceptionally well in marine applications such as rigging, cabling, and securing components, where corrosion and degradation are perennial problems.

Further, the 35 awg wire’s lightweight character, coupled with its robust strength, fulfills the imperative need for materials that provide reliability while also adhering to stringent weight constraints in aerospace. As a structural tie, its slender form and resilience are crucial to maintaining structural integrity in construction and architecture. Moreover, in electronic manufacturing, the wire’s slim profile facilitates electrical conductivity in a compact format, thus fulfilling the prerequisite of miniaturisation and maintaining electrical performance. It is also useful for jewelry making. It can be manipulated into intricate designs while maintaining longevity and aesthetics under a variety of circumstances. This versatile, durable, and reliable wire offers a comprehensive solution to demands that require micro-sizing in SS316L without compromising strength and resilience across multiple verticals.

Specification of Wire:

- Diameter – 0.14mm (140 Micron – 35 AWG)

- Ohms/ft – 46.10

We also offer this grade as ribbon wire and flat wire too if required.

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

Not only do we offer 304 grade stainless steel wire, but we also stock huge levels of SS316, SS430 (magnetic) and SS317L.

We also offer stainless steel in ribbon and flat wire options.

The choice is virtually endless!

FAQs About This Wire

Is Stainless Steel 316L 35 AWG Wire Certified For Aerospace Use?

The certification of Stainless Steel 316L, especially in a specific gauge like 35 AWG, for aerospace use may vary depending on regional and international standards. To ensure safety and durability, the aerospace industry has stringent material standards, often requiring specific testing and certifications, such as AMS (Aerospace Material Specifications). In aerospace applications, SS316L is renowned for its outstanding corrosion resistance, especially in saline environments, as well as its impressive strength-to-weight ratio. However, it is essential for 35 AWG SS316L wire to be certified by the manufacturer or distributor as compliant with relevant aerospace industry standards.

SS316L 35 AWG wire from some manufacturers may adhere to universal or specific industry standards, making it suitable for aerospace use. To make sure a wire meets the stringent requirements of aerospace applications, it is necessary to verify its conformity to requisite standards through technical datasheets, certifications, and potentially sample testing. As a result, a dialogue with the wire manufacturer is essential for confirming that the wire adheres to standards like tensile strength, elongation, and corrosion resistance. Therefore, while SS316L wire can be considered beneficial to aerospace, the explicit certification must be affirmed through meticulous validation of its specifications.

Is SS316L 35 AWG SS316L Wire Safe For Skin Contact?

SS316L stainless steel, particularly in a 35 AWG gauge, is commonly regarded as safe for skin contact for most people, and is frequently utilized in applications that require biocompatibility and corrosion resistance, such as in medical devices and jewelry. The “L” in SS316L denotes its low carbon content, which enhances its anti-corrosion properties, especially when in contact with human skin, which can excrete sweat and oils that are potentially corrosive. Furthermore, SS316L does not contain nickel in high concentrations, which is often the culprit for allergic reactions from metal objects.

However, while the majority of individuals may not experience skin irritation when in contact with SS316L wire, there’s always a small possibility that some might exhibit sensitivities or allergic reactions, particularly if they have a history of metal allergies. In instances where the wire is intended to be utilized in close contact with skin – such as in wearable devices, jewelry, or medical applications – it’s prudent to ensure that the wire has undergone biocompatibility testing according to relevant standards (e.g., ISO 10993) to ascertain its safety and suitability for such use. Always ensure to refer to manufacturer data sheets and certifications to verify that the 35 AWG SS316L wire is deemed safe and has been tested for skin contact applications.

How Does 35 AWG SS316L Wire Perform In Extreme Temperatures?

35 AWG SS316L wire exhibits commendable performance under extreme temperatures, given its intrinsic properties derived from the 316L stainless steel alloy. Noteworthy for its high melting point, which is approximately 1400°C (2550°F), and its remarkable resistance to oxidation in elevated temperatures up to around 870°C (1600°F), SS316L maintains its structural integrity and doesn’t succumb easily to scaling in high-temperature scenarios. Moreover, its low carbon content (denoted by the ‘L’ in 316L) enhances its resistance to sensitisation. This is a phenomenon occurring in welded stainless steel at temperatures between approximately 425°C and 850°C (797°F and 1572°F). It leads to reduced corrosion resistance. On the flip side, in extremely cold environments, SS316L does not become brittle and maintains its toughness, providing reliability in applications that require exposure to sub-zero temperatures.

Consequently, 35 AWG SS316L wire finds its utility in various applications demanding robustness in extreme temperatures, such as in industrial heating, aircraft construction, and certain scientific applications where stability under thermal stress is requisite. However, it’s prudent to always consult the material’s specification sheet for precise data on temperature limits and performance to ensure that the wire is suitable for the specific temperature ranges required in a given application. Additionally, factors such as tensile strength, elongation, and resistivity, which might shift with temperature fluctuations, should be considered to determine the wire’s efficacy and safety in specific high or low-temperature contexts.

The Crazy Wire Company is a leading UK based supplier of nichrome, FeCrAl, and stainless steel wires. We specialise in rapid delivery to any location around the country. Our factory is located in Warrington, which is the historic home of the UK’s wire industry.

Check out our blog ‘What You Need To Know About: Stainless Steel Wires’ for more information on resistance wire in general. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.