Description

Twisted Nichrome Resistance Wire

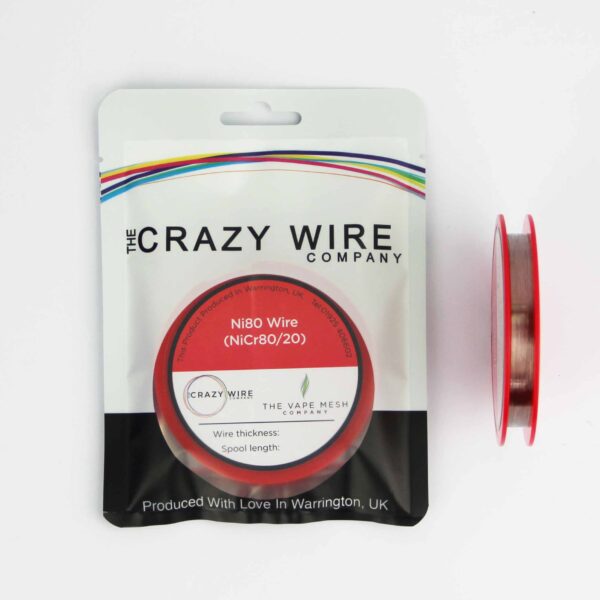

The Ni80 Nichrome Resistance Wire is a versatile and durable product, primarily used in various applications requiring high-temperature resistance and low electrical resistance. With a selection of gauges, including 24, 26, 28, 30, and 32 AWG, this wire caters to a variety of needs. The spools each contain 10 meters of wire, which ensures that the wire can be used for a variety of purposes.

A key characteristic of this wire is that it is made with an alloy of nickel (80%) and chromium (20%), resulting in excellent properties. The high nickel content makes it resistant to oxidation and corrosion, making it suitable for environments where these factors are a concern. Furthermore, the chromium component strengthens its durability and temperature resistance, enabling it to withstand high temperatures without deteriorating.

Specification of Wire:

- Diameter – 24, 26, 28, 30, 32 AWG Twist – Fine Wire.

Technical Specification:

- Ni – Rest

Cr – 20.0 – 23.0

Fe – <1.0 - Max Continuous Service Temp Of Element – 1200

- Micrographic Structure – Austenite

- Magnetic Properties – Nonmagnetic

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

We do not only offer Ni80 wire. We also have a huge range of KA1 and stainless steel wire in immediate stock too.

Ribbon wire and flat wire are stocked for immediate dispatch too.

FAQs About This Wire

How Does Nichrome Wire Compare To Stainless Steel Wire In Terms Of Durability?

- Corrosion Resistance: Stainless steel wire generally has better corrosion resistance compared to nichrome wire. It is less likely to rust or degrade in humid or corrosive environments, making it suitable for outdoor or marine applications. Nichrome, though resistant to high temperatures, can be more susceptible to corrosion under certain conditions.

- Temperature Resistance: Nichrome wire excels in high-temperature applications. It can withstand higher temperatures without losing strength or deforming, making it ideal for heating elements and industrial furnaces. Stainless steel wire, while also having good heat resistance, is not as effective at extremely high temperatures.

- Electrical Resistance: Nichrome wire has a higher electrical resistance than stainless steel, which makes it more suitable for applications where electrical heating is required. This property allows nichrome to convert electrical energy into heat more efficiently.

- Flexibility and Strength: Stainless steel wire is generally stronger and more durable in terms of withstanding mechanical stress and wear. It’s preferred in structural applications where strength is a critical factor. Nichrome wire, while flexible, is not as strong and is more prone to breakage under mechanical stress.

- Lifespan in Specific Environments: The lifespan of each type of wire depends heavily on the environment in which it’s used. Nichrome wire is more durable in high-temperature environments where heat resistance is crucial, while stainless steel is more durable in corrosive environments.

How Does The Nickel-Chromium Ratio Affect The Wire’s Properties?

The nickel-chromium ratio in Nichrome wire plays a pivotal role in defining its properties, tailoring it to various applications. A higher chromium content improves electrical resistance, which is crucial for precise heating applications, as well as corrosion resistance, which is crucial in harsh environments. On the other hand, nickel contributes to the strength and ductility of the wire, facilitating its use in shaping and forming applications.

Besides influencing the wire’s temperature resistance, chromium aids in maintaining structural integrity at high temperatures, making it ideal for heating elements and industrial furnaces. A wire’s melting point is further affected by the amount of chromium, with a higher concentration of chromium allowing application at higher temperatures. Due to the different costs of nickel and chromium, the cost and availability of Nichrome wire are also affected by this ratio. It is therefore crucial to choose the right nickel-chromium composition for Nichrome wire if it is to be optimised for specific applications, balancing electrical resistance, durability, flexibility, and cost-effectiveness.

Check out our blog expanding on the difference between Clapton and Flapton coil wires. This is an extremely detailed article, which we hope will provide much insight into the subject.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.