Description

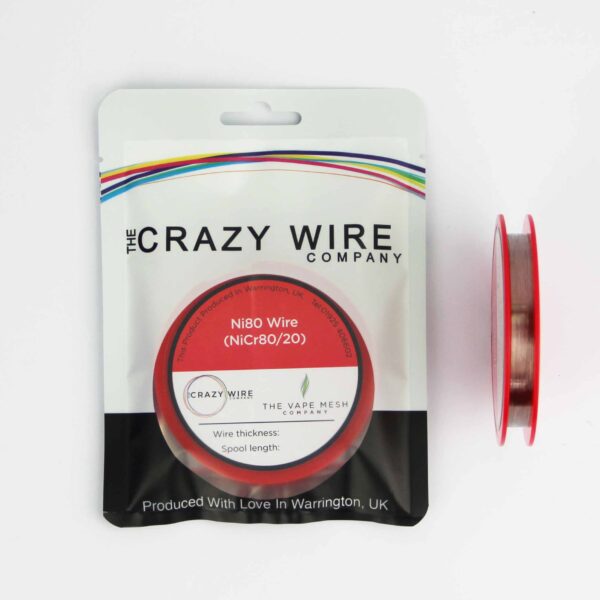

0.37mm Nickel Chrome Alloy Heat Treatment Wire

The Crazy Wire Company are well known as suppliers of top quality Ni80 alloy heat treatment wire. We have enormous stock levels at all times, as we use this wire to weave our high specification woven mesh products. Our brilliant staff are experts in producing our spools of round wire on our 6 rapid action winding machines. All spools are produced to carry a little extra length to make up for any waste when handling the product.

The 0.37mm (27 AWG) nickel chrome alloy heat treatment wire is an advanced and highly dependable product tailored for a variety of industrial and domestic applications. Its nickel and chrome blend ensures exceptional conductivity and durability, ensuring durability for a long time to come. Due to its heat resistance, it is perfect for applications that require elevated temperatures. This alloy heat treatment wire is resistant to oxidation and corrosion. This ensures prolonged wire lifespan and maintains its conductivity over time.

A thickness of 0.37mm or 27 AWG makes it suitable for intricate work, where precision is crucial, but also robust enough for large-scale applications. Many industries can benefit from its versatile applications, including electronics, ceramics, aerospace, and even medicine. Its versatility and reliability make this wire a popular choice for coil making, furnace elements, resistor circuits, and even specialised heater units.

It is primarily used as a resistance heating electric wire because nichrome 80 is a non-magnetic alloy composed of nickel and chrome. As a general rule, the alloy commonly supplied contains 80% nickel and 20% chrome by weight. However, there are numerous variations available based on the basic formulation that may suit a particular application. Electric ovens, toasters and hair dryers use this element because of its relatively high electrical resistivity and resistance to oxidation.

Key product details:

- Diameter – 0.37mm (370 Micron – 27 AWG)

- Ohms/m – 10.14

- Technical Specification:

- Ni – Rest

- Cr – 20.0 – 23.0

- Fe – <1.0

- Max Continuous Service Temp Of Element – 1200

- Micrographic Structure – Austenite

- Magnetic Properties – Nonmagnetic

- Electrical resistance is high

- Corrosion resistance is high

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

We do not only offer Ni80 round wire. We also have a huge range of KA1 and stainless steel round wire in immediate stock too.

Ribbon wire and flat wire are stocked for immediate dispatch too.

FAQs About This Wire

Which Is A Good Alloy Heat Treatment Wire?

A good alloy for heat treatment wire is one that has high resistance to heat and high melting temperature, as well as good thermal conductivity and electrical conductivity. Some common alloys used for heat treatment wire include:

Nichrome: Nichrome is a nickel-chromium alloy that is known for its high resistance to heat and high melting temperature. It is commonly used in heating elements and resistors.

KA1: KA1 is another nickel-chromium alloy that is commonly used in heating elements and high-temperature applications. It is known for its good thermal conductivity and high resistance to oxidation and corrosion.

Inconel: Inconel is a nickel-chromium-based superalloy that is known for its high resistance to heat and corrosion. It is often used in high-temperature applications, such as furnace linings and heating elements.

Titanium: Titanium is a strong and lightweight metal that is known for its high resistance to heat and corrosion. It is often used in high-temperature applications, such as furnace linings and heating elements.

The choice of alloy for heat treatment wire will depend on the specific requirements of the application, such as temperature range, corrosion resistance, and thermal conductivity. In some cases, a custom alloy may be needed to meet the specific needs of a particular application.

How Do I Solder Nichrome Wire?

Here are the steps to solder nichrome wire:

- Gather materials: You will need a soldering iron, a high-temperature solder, and nichrome wire.

- Clean the wire: Clean the end of the nichrome wire that you want to solder by wiping it with a clean cloth.

- Tin the wire: Apply a small amount of high-temperature solder to the end of the nichrome wire. This is known as “tinning” the wire.

- Heat the wire and component: Use the soldering iron to heat the tinned end of the nichrome wire and the component that you want to join it to.

- Apply solder: Touch the tinned end of the nichrome wire to the component and apply a small amount of solder to the joint. The solder should melt and flow into the joint, connecting the nichrome wire to the component.

- Cool and inspect: Allow the joint to cool completely. Then inspect it to ensure that it is secure and free of any defects.

It is important to note that nichrome wire has a high resistance to heat and can be difficult to solder. It is recommended to use a high-temperature soldering iron and high-temperature solder, and to pre-tin the nichrome wire before attempting to join it to another component. Additionally, it is important to follow proper safety precautions and use proper ventilation when soldering nichrome wire.

How Can I Control The Temperature Of Nichrome Wire?

There are several methods to control the temperature of Nichrome wire, including the use of temperature controllers, thermocouples, and power controllers.

- Temperature controllers: A temperature controller is a device that allows you to set a specific temperature and maintain it by controlling the power to the Nichrome wire. This can be done using a relay or a solid-state switch to turn the power on and off as needed.

- Thermocouples: A thermocouple is a device that measures the temperature of the Nichrome wire and sends a signal to a controller, which adjusts the power to the wire to maintain the desired temperature.

- Power controllers: A power controller is a device that regulates the amount of power being supplied to the Nichrome wire in order to control its temperature. This can be done using a potentiometer, a rheostat, or a solid-state switch.

In each case, the precise control method will depend on the specific requirements of the application, including the temperature range, the desired level of control, and the complexity of the setup. It is important to use a power controller that is rated for the maximum power that the Nichrome wire will consume in order to ensure safe and reliable operation.

Does Nichrome Wire Rust?

Check out our blog ‘what is nichrome‘ for more information on ni80 wire in general. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.