Description

Nickel Chrome Cutting Hot Wire

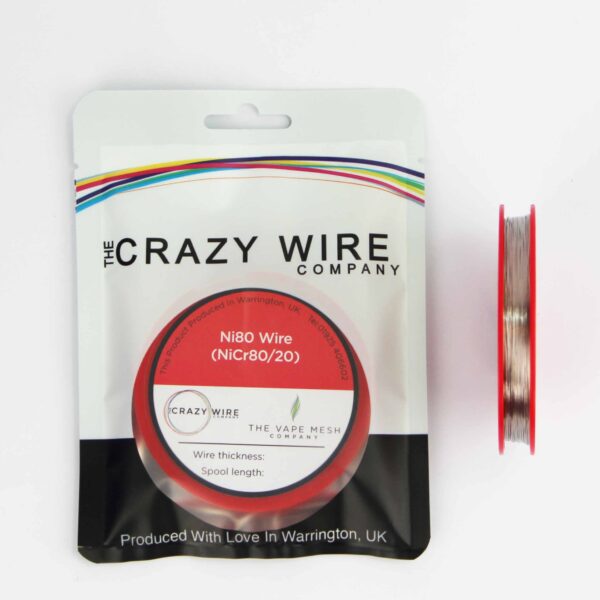

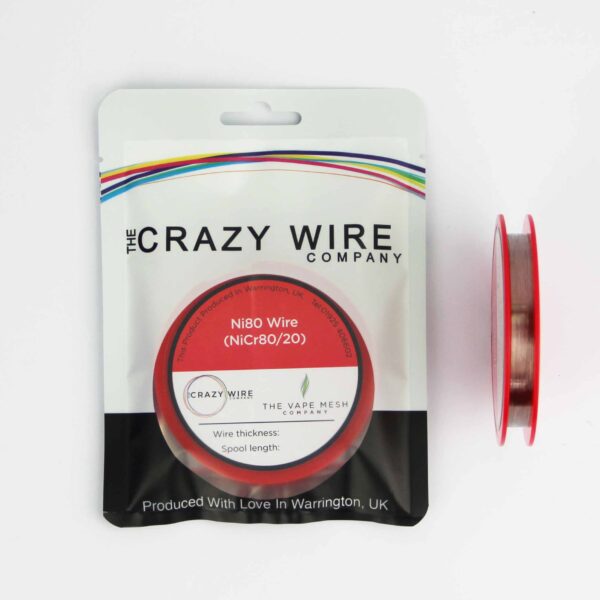

The Crazy Wire Company are best know as suppliers of top quality nickel chrome cutting hot wire. We have enormous stock levels at all times, as we use this wire to weave our marine grade woven mesh products. Our brilliant staff are experts in producing our spools of round wire on our 6 rapid action winding machines. All spools are produced to carry a little extra length to make up for any waste when handling the product.

The 0.16mm (34 AWG) Ni80 Nickel Chrome cutting hot wire is a versatile and durable product designed for precision cutting applications. Nickel-chrome alloy wire offers superior resistance to oxidation and corrosion, making it suitable for prolonged use in various environments. Its 0.16mm diameter ensures precision cuts while minimising breakage risk thanks to its strength and flexibility.

With its heat resistance and conductivity, the wire warms up rapidly, keeping a consistent temperature for efficient cutting. A few of its primary applications include molding foam, shaping thermoplastics, trimming synthetic fabrics, and creating intricate patterns. Furthermore, industries from manufacturing to artistry appreciate its clean, sharp lines. Ni80 Nickel Chrome cutting hot wires provide consistent quality, long lifespan, and superior cutting performance.

0.16mm Nichrome wire refers to a wire made of an alloy of nickel and chromium, with a diameter of 0.16mm. This size of Nichrome wire is commonly used in applications such as heating elements and resistance wire, where its high resistance to corrosion and high electrical resistivity make it ideal.

The electrical resistance of Nichrome wire can be calculated using the formula:

R = ρ * L / A

Where:

- ρ (rho) is the resistivity of Nichrome, usually given in units of Ohm-meters

- L is the length of the wire

- A is the cross-sectional area of the wire, usually given in square millimeters (mm^2)

The exact resistance of a 0.16mm Nichrome wire will depend on the specific composition and resistivity of the Nichrome alloy, as well as the length and cross-sectional area of the wire.

Key product details:

- Diameter – 0.16mm (160 Micron – 34 AWG)

- Ohms/m – 54.21

- Technical Specification:

- Ni – Rest

- Cr – 20.0 – 23.0

- Fe – <1.0

- Max Continuous Service Temp Of Element – 1200

- Micrographic Structure – Austenite

- Magnetic Properties – Nonmagnetic

- Electrical resistance is high

- Corrosion resistance is high

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

We do not only offer Ni80 round wire. We also have a huge range of KA1 and stainless steel round wire in immediate stock too.

Ribbon wire and flat wire are stocked for immediate dispatch too.

FAQs About This Wire

How To Cut Foam With Hot Wire

Cutting foam with a hot wire involves heating a thin wire to a high temperature and using it to melt and cut through the foam. This method is often used for cutting foam for use in craft projects, packaging, and insulation. Here are the steps to cut foam with a hot wire:

- Gather materials: You will need a hot wire foam cutter, which typically consists of a heating element, a wire, and a power supply. You will also need a piece of foam to cut.

- Set up the hot wire foam cutter: Follow the manufacturer’s instructions to set up the hot wire foam cutter. This typically involves connecting the heating element to the power supply and installing the wire in the appropriate location.

- Heat the wire: Turn on the power supply to heat the wire. The wire should reach a temperature high enough to melt the foam.

- Cut the foam: Place the foam on a flat surface and use the hot wire to cut through the foam along your desired line. Move the hot wire slowly and evenly to make a clean cut.

- Turn off the power supply: When you have finished cutting the foam, turn off the power supply to stop heating the wire.

Will A Hot Wire Cutter Cut Polystyrene?

Yes, a hot wire cutter can be used to cut polystyrene (also known as Styrofoam). Polystyrene is a type of foam that is perfect for using as insulation, packaging, and as a base material for craft projects. Because polystyrene is a thermoplastic material, it can be easily melted and cut with a hot wire.

The process of cutting polystyrene with a hot wire cutter is similar to cutting other types of foam. The wire is heated to a high temperature, and the heat is used to melt the foam as the wire is moved through it. This allows for precise cuts and eliminates the need for sawing or other cutting methods that can be messy or difficult.

However, it’s important to note that cutting polystyrene with a hot wire can produce fumes that can be hazardous to breathe. It’s recommended to work in a well-ventilated area and wear a protective mask to avoid inhaling the fumes.

Can You Cut PVA Glue With Hot Wire?

No, cutting PVA (polyvinyl acetate) glue with a hot wire is not possible as PVA glue is a non-thermoplastic material and does not melt. A hot wire cutter works by heating a wire to a high temperature and using it to melt and cut through thermoplastic materials such as foam. PVA glue does not have a melting point and does not change its physical form when exposed to heat, so it cannot be cut with a hot wire.

If you need to cut PVA glue, you would need to use a different method, such as cutting it with a sharp blade or scissors, breaking it, or dissolving it with a solvent. The specific method you choose will depend on the application and the desired outcome.

How Does The Length Of A Wire Affect Resistance?

The length of a wire affects its resistance because the longer a wire is, the more its resistance increases. This relationship is described by Ohm’s law, which states that the resistance of a wire is directly proportional to its length.

Mathematically, the resistance of a wire can be expressed as:

R = ρ * L / A

Where:

- R is the resistance of the wire

- ρ (rho) is the resistivity of the material the wire is made of

- L is the length of the wire

- A is the cross-sectional area of the wire

As the length of the wire increases, the resistance of the wire also increases, because the electrons must travel a longer distance through the wire, encountering more obstacles and collisions along the way. This results in a higher resistance to the flow of electrons, and a higher overall resistance of the wire.

In practical applications, the length of a wire can have a significant impact on its resistance, especially when designing circuits and electrical systems where resistance plays a critical role. To reduce the resistance of a wire, one could either reduce the length of the wire, increase the cross-sectional area of the wire, or use a material with lower resistivity.

Can I Weld Nichrome Wire?

Yes, it is possible to weld Nichrome wire. Nichrome is an alloy of nickel and chromium, and it is known for its high resistance to heat and corrosion. Because of its high resistance, Nichrome wire is often used in high-temperature applications such as heating elements and thermocouples.

However, welding Nichrome wire can be challenging because of its high resistance and tendency to oxidize at high temperatures. When welding Nichrome wire, it’s important to use a welding process that is suitable for high-resistance materials, such as resistance welding or electron beam welding.

In resistance welding, the Nichrome wire is clamped between two electrodes and a current is passed through the wire, creating heat that melts the ends of the wire, fusing them together. In electron beam welding, a beam of high-energy electrons is used to melt and fuse the Nichrome wire.

Both of these welding methods require specialised equipment and skills, and it’s recommended to work with a professional who has experience welding high-resistance materials like Nichrome wire. It’s also important to consider the thermal and electrical properties of the Nichrome wire when designing a welding process, to ensure a strong and reliable weld.

Check out our blog ‘what is nichrome’ for more information on ni80 wire in general. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

Reviews

There are no reviews yet.