When choosing copper wire for electrical, industrial, or crafting applications, one of the most common decisions is between bare copper wire and tinned copper wire. While both types offer excellent conductivity and versatility, there are key differences in terms of corrosion resistance, durability, and specific use cases.

In this article, we’ll break down what sets them apart, their pros and cons, and when to use each type.

What is Bare Copper Wire?

Bare copper wire is exactly what it sounds like—pure copper wire without any coating or protective layer. It is the most common type of copper wire and is widely used in electrical wiring, DIY projects, grounding applications, and general-purpose electrical work.

Since bare copper wire has no insulation or plating, it maintains its high conductivity but is more vulnerable to oxidation and corrosion over time, especially in humid or marine environments.

Pros of Bare Copper Wire:

✔ Higher conductivity – Pure copper ensures maximum electrical efficiency.

✔ Lower cost – Generally cheaper than tinned copper wire.

✔ Easier to solder – Ideal for electrical applications requiring strong connections.

✔ Good for grounding – Commonly used for earth grounding due to its conductivity.

Cons of Bare Copper Wire:

❌ Susceptible to oxidation – Can corrode over time, especially in moist environments.

❌ Less durable in marine or outdoor settings – May degrade faster in harsh conditions.

What is Tinned Copper Wire?

Tinned copper wire is simply bare copper wire coated with a thin layer of tin. This tin coating enhances the wire’s corrosion resistance, making it more suitable for marine, outdoor, and high-humidity environments.

The tin layer does not affect electrical conductivity significantly, but it provides a protective barrier against oxidation, making it a longer-lasting option for certain applications.

Pros of Tinned Copper Wire:

✔ Superior corrosion resistance – Ideal for marine, outdoor, and industrial applications.

✔ Longer lifespan – Tin coating prevents copper from oxidising.

✔ Better soldering properties – Tin plating makes soldering easier in some cases.

✔ Improved durability in extreme conditions – Less affected by moisture, heat, and chemicals.

Cons of Tinned Copper Wire:

❌ Slightly lower conductivity than bare copper – The tin layer introduces minimal resistance.

❌ More expensive – Costs more than standard bare copper wire.

❌ Less commonly used for general wiring – More specialised for extreme environments.

Key Differences: Bare Copper Wire vs Tinned Copper Wire

| Feature | Bare Copper Wire | Tinned Copper Wire |

|---|---|---|

| Conductivity | Higher conductivity (pure copper) | Slightly lower due to tin coating |

| Corrosion Resistance | Susceptible to oxidation | Highly resistant to corrosion |

| Durability in Moist Areas | Less durable in humidity | Ideal for humid & marine conditions |

| Ease of Soldering | Excellent | Easier due to pre-tinned surface |

| Cost | More affordable | More expensive due to tin coating |

| Best Uses | Grounding, indoor electrical work | Marine, outdoor, industrial settings |

Which One Should You Use?

The choice between bare copper wire and tinned copper wire depends on your specific application and environment.

Use Bare Copper Wire if:

- You need the highest electrical conductivity (e.g., grounding systems).

- The wire will be used indoors or in dry environments.

- You are looking for a cost-effective solution.

Use Tinned Copper Wire if:

- The wire will be exposed to moisture, humidity, or marine conditions.

- You want a longer-lasting wire with better corrosion resistance.

- You need an easier-to-solder wire for certain applications.

Applications of Bare Copper and Tinned Copper Wire

| Application | Recommended Wire Type | Why? |

|---|---|---|

| Household Wiring | Bare Copper Wire | Maximum conductivity, cost-effective. |

| Marine Wiring | Tinned Copper Wire | Prevents corrosion from saltwater. |

| Automotive Wiring | Tinned Copper Wire | Withstands moisture, heat, and vibration. |

| Grounding Systems | Bare Copper Wire | High conductivity, cost-effective. |

| Solar Panel Wiring | Tinned Copper Wire | Longer-lasting in outdoor conditions. |

| Aerospace & Industrial | Tinned Copper Wire | Increased durability in extreme settings. |

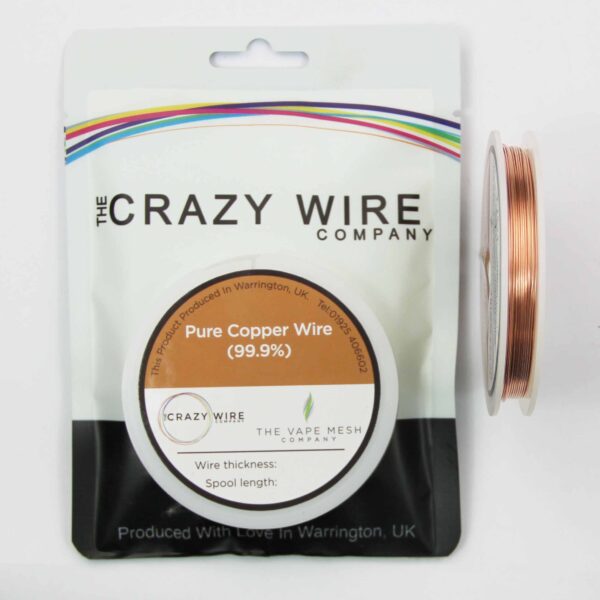

Why Choose The Crazy Wire Company for Copper Wire?

At The Crazy Wire Company, we supply high-quality bare copper wire that delivers superior conductivity and flexibility for various applications. Our 99% pure bare copper wire is the perfect solution for electrical projects, crafting, and general-purpose use.

✔ High-Purity Copper – Ensures excellent electrical performance.

✔ Fast UK Shipping – Immediate dispatch from our warehouse.

✔ Competitive Pricing – Get premium copper wire at the best rates.

✔ Expert Support – Need advice? Our team is here to help!

Both bare copper wire and tinned copper wire have their advantages. If you need maximum conductivity and cost-effectiveness, go for bare copper wire. If your project involves humidity, water exposure, or extreme environments, then tinned copper wire is the better choice.

At The Crazy Wire Company, we offer a range of high-quality copper wires to suit all applications.

Explore our premium copper wire range today and get the best wire for your next project!

We offer also a massive range of stainless steel wire and nichrome wire through our store. Choose the wire that you want to work with and we’ll get spooling.

If you’re interested in learning more about wire, check out our other blog on Everything You Need to Know About Wires.

We are also proud to supply this product on our highly popular eBay store, check us out there too.

Thank you for checking out our site.

- MULTIBUY SAVINGS – ORDER 5 FOR 20% OFF

- FREE UK Delivery For All Orders Over £25

- Immediate Express Dispatch From Stock

- Orders Fulfilled From Warrington, UK

- Tracked Delivery with Order Updates

- 30-Day Unused Returns Accepted