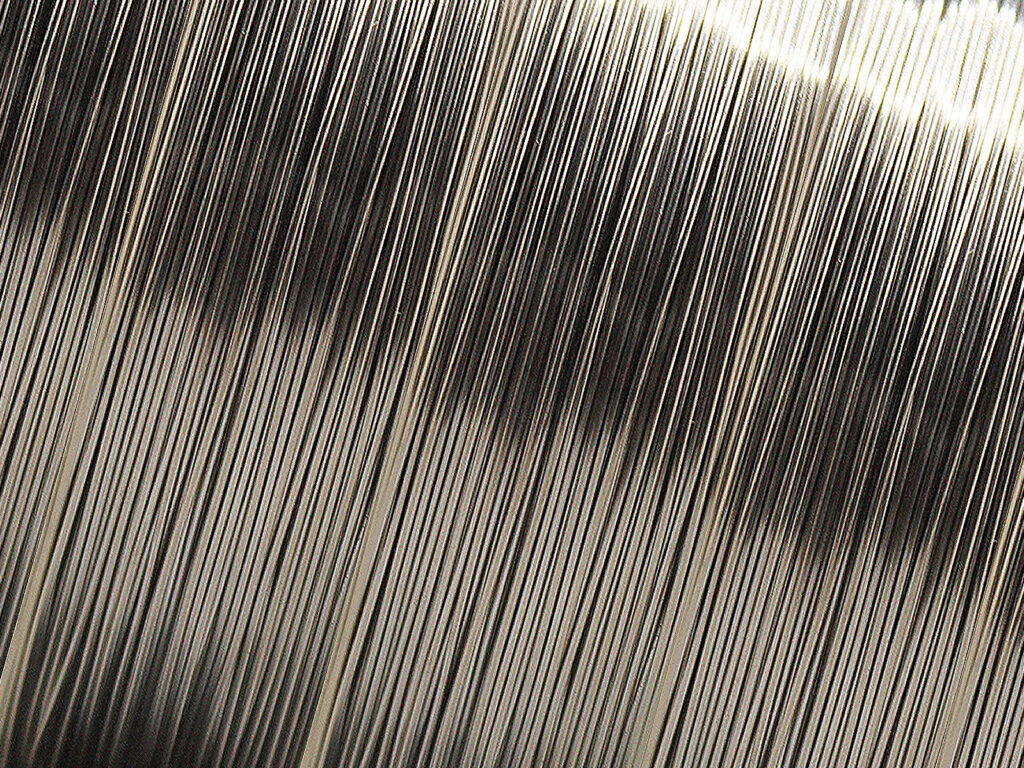

In the world of wires, especially those utilised in heating applications, a few names consistently emerge as champions: Nichrome vs Stainless Steel vs KA1. These materials are often the top choices for various applications, from heating elements in toasters and industrial furnaces to construction applications. But which one stands tall among the rest? Let’s dive deep into this ultimate wire showdown.

1. Introduction to the Contenders:

Nichrome: A non-magnetic alloy of nickel and chromium, nichrome is popular for its high resistance and stability at high temperatures.

Stainless Steel (SS): An iron-based alloy containing chromium (typically at least 10.5% to 11%), SS is known for its corrosion resistance and has myriad applications, from kitchen appliances to surgical instruments.

FeCrAl A1 (often called Kanthal A1): An iron-chromium-aluminium alloy, FeCrAl A1 is best known in the wire industry as Kanthal A1. It boasts excellent resistance to oxidation and has a high melting point.

2. Physical Properties:

Melting Point:

- Nichrome: Approx. 1400°C

- Stainless Steel: Varies between 1400°C to 1500°C depending on the grade

- FeCrAl A1: Approx. 1500°C

Here, FeCrAl A1 takes the edge due to its slightly higher melting point compared to its competitors.

Thermal Conductivity:

- Nichrome: Lower than both SS and FeCrAl A1, making it efficient for heating elements as it centralises heat.

- Stainless Steel: Moderate.

- FeCrAl A1: Higher than Nichrome but lesser than some grades of stainless steel.

For applications requiring focused heating, Nichrome might be the preferred choice, but FeCrAl A1 provides a balanced performance.

3. Resistance to Oxidation:

Corrosion and oxidation resistance is vital for longevity in many applications.

Nichrome: Offers excellent oxidation resistance and often forms a protective layer to prevent further oxidation.

Stainless Steel: The chromium present forms a passive oxide layer, giving stainless steel its iconic corrosion resistance. However, in some high-temperature applications, SS might not fare as well as Nichrome or KA1.

FeCrAl A1: It possesses superb resistance to oxidation at high temperatures, thanks to the presence of aluminum.

In this regard, while all three contenders are admirable, KA1 and Nichrome stand out for high-temperature applications.

4. Mechanical Properties:

Nichrome: While it’s pliable and easy to work with, its tensile strength is lower than stainless steel.

Stainless Steel: Known for its robustness and durability. However, its workability might be a challenge, depending on the grade.

FeCrAl A1: Falls in between Nichrome and Stainless Steel in terms of tensile strength and malleability.

5. Cost & Availability:

Nichrome: Relatively affordable and widely available.

Stainless Steel: Widely available in numerous grades, offering versatility. Cost can vary based on the grade and quality.

FeCrAl A1: Slightly pricier than Nichrome, but its performance often justifies the cost.

6. Specific Use Cases:

Nichrome:

- Household Appliances: Used in devices like toasters, electric ovens, and hair dryers due to its quick heating capability.

- Laboratory Equipment: Found in specific tools and instruments that require consistent heating at high temperatures.

- Industrial Heating: Used in certain kilns and furnaces that demand consistent and high-temperature heat sources.

Stainless Steel (SS):

- Culinary Applications: Used in cutlery, cookware, and kitchen appliances for its non-reactive nature.

- Construction: Valued in infrastructure projects and architectural facades for its structural strength and aesthetics.

- Medical Uses: Stainless Steel grades are used in surgical instruments, medical equipment, and certain implants due to biocompatibility.

- Maritime Applications: Favored in shipbuilding and marine equipment for its resistance to rust.

FeCrAl A1 (often called KA1):

- Industrial Furnaces: Preferred material due to its high melting point and consistent performance under extreme heat.

- Household Heating: Used in electric heaters and specific oven elements for its heat resistance and longevity.

- Specialised Manufacturing: Employed in the production of ceramics or glass where dependable heating elements are essential.

Advantages: Nichrome vs Stainless Steel vs KA1

Nichrome is especially known for its stability at high temperatures. This unique attribute allows it to maintain both its structure and resistance properties even under intense heat. Many household appliances rely on this feature, opting for Nichrome because of its rapid heating capabilities. With a quick ramp-up time, Nichrome delivers heat almost instantaneously when powered. Furthermore, its interaction with oxygen leads to the formation of a protective chromium oxide layer. This not only guards the wire against further degradation but also makes it more durable in various environments. Additionally, its non-magnetic nature is a boon for applications where magnetism could be detrimental. Lastly, its high resistivity marks it as an excellent choice for resistance wire applications, where specific heat outputs are necessary.

Stainless steel stands as a symbol of resilience and durability, primarily due to its exceptional resistance to rust and corrosion. This resistance, imparted by its chromium content, ensures its longevity, especially in moist or corrosive environments. But it’s not just about durability. Stainless steel is inherently strong, boasting a high tensile strength that withstands wear and tear. This strength doesn’t mean a compromise on variety; there are numerous grades of stainless steel available, each catering to specific needs. Whether it’s a requirement for more strength, enhanced corrosion resistance, or better machinability, there’s likely a stainless steel grade suited for the purpose. Aesthetically, stainless steel offers a bright and shiny appearance, making it a favorite for visible parts or decorative applications. Moreover, certain grades have biocompatible properties, making stainless steel a staple in medical equipment and even implants.

When it comes to withstanding incredibly high temperatures, FeCrAl A1 emerges as a top contender. Its composition allows it to brave intense heats, marking it as an ideal choice for industrial furnaces and other high-temperature applications. But it’s not just about bearing the heat. FeCrAl A1 is characterised by its superior resistance to oxidation. Thanks to the aluminum in its alloy, it forms a protective alumina layer when exposed to oxygen, especially at elevated temperatures. This characteristic ensures consistent performance and resistivity over time, making it a reliable choice for various applications. Furthermore, this resistance attributes to its longevity, ensuring that FeCrAl A1 wires endure longer, especially when compared to some of its counterparts in high-temperature settings. While its initial cost might be a tad higher than some other wire materials, the long-term benefits, in terms of performance and lifespan, often justify the investment.

Nichrome vs Stainless Steel vs KA1 and choosing between them boils down to the specific application and requirements. While Nichrome is a staple in many household devices, Stainless Steel’s versatility makes it a favorite in various industries. Meanwhile, FeCrAl A1’s stellar performance in high-temperature applications is unparalleled.

One might excel in a particular domain, but all three remain industry stalwarts, ensuring optimal performance across multiple sectors. The ultimate choice, as always, lies in the fine details of the job at hand.

If you’re interesting in learning more about wire, check out our other blog on Everything You Need to Know About Wires.

We are also proud to supply this product on our highly popular eBay store, check us out there too.

Thank you for checking out our blog.

Nichrome Wire Safety: Top Tips for Working Safely

Best Wire for Electronics Projects

Is Ni80 Wire Suitable for DIY Heating Elements

Wire Grades Explained

How Wire Diameter Affects Strength and Flexibility

How to Cut and Shape Wire for Custom Applications

Can Wire Be Used in 3D Printing?

How Wire Composition Affects Conductivity