Wire is a versatile material used in everything from jewellery making to industrial manufacturing. The ability to cut and shape wire correctly ensures precision, safety, and durability in any project. Whether you’re working with Copper, Stainless Steel, Nichrome, or FeCrAl Wire, selecting the right tools and techniques is essential.

At The Crazy Wire Company, we provide a wide range of high-quality wires suited for custom applications. This guide covers the best methods for cutting, shaping, and handling wire to achieve professional results.

Why It’s Important to Cut and Shape Wire Properly

Properly cutting and shaping wire prevents material wastage and ensures clean, accurate results. Key benefits include:

✅ Improved Accuracy – Essential for electrical connections, crafting, and structural components.

✅ Reduced Material Waste – Cutting efficiently minimises excess use.

✅ Enhanced Durability – Proper techniques prevent wire from weakening or breaking.

✅ Professional Appearance – Clean cuts and precise bends improve the quality of the final product.

✅ Safety – Prevents injuries caused by jagged edges or excessive force.

Choosing the Right Wire for Your Project: How to Cut and Shape Wire Effectively

Before cutting or shaping, selecting the appropriate wire type is crucial. Below is a comparison of popular wire materials and their best uses:

| Wire Type | Composition | Best Uses |

|---|---|---|

| Copper Wire | Pure Copper | Electrical wiring, jewellery, DIY crafts |

| Stainless Steel Wire | Iron-Chromium-Nickel | Industrial applications, marine environments |

| Nichrome Wire | Nickel-Chromium | Heating elements, foam cutting tools |

| FeCrAl Wire | Iron-Chromium-Aluminium | High-temperature resistance applications |

| Aluminium Wire | Pure Aluminium | Lightweight electrical applications, sculpture making |

✅ Tip: If flexibility is needed, copper and aluminium wires are easier to shape. For high durability, stainless steel and FeCrAl wire offer better resilience.

Best Tools for Cutting and Shaping Wire

Different projects require specific tools to achieve precision cuts and bends. The right tool will depend on the wire’s thickness and material type.

1. Cutting Tools

✔ Wire Cutters – Ideal for soft wires like copper and aluminium.

✔ Bolt Cutters – Necessary for cutting thick, hard wires such as stainless steel.

✔ Flush Cutters – Provides clean, precise cuts with minimal distortion.

✔ Rotary Tools with Cutting Discs – Great for cutting thick metal wires cleanly.

2. Shaping Tools

✔ Pliers (Round Nose, Flat Nose, and Chain Nose) – Perfect for bending and forming intricate shapes.

✔ Mandrels and Jigs – Help create uniform coils and loops.

✔ Hammers and Anvils – Used for flattening or texturing wire.

✔ Rolling Mills – Shapes wire into different thicknesses for precision applications.

✅ Tip: Always Match Your Tool to the Wire Gauge to Cut and Shape Wire Without Damage

How to Cut Wire Safely and Accurately

When cutting wire, ensuring clean, burr-free edges is essential for both functionality and aesthetics. Follow these steps for a precise cut:

✔ Step 1: Choose the Right Cutter – Select a tool appropriate for the wire type and gauge.

✔ Step 2: Secure the Wire – Use a vice or hold it firmly to prevent movement.

✔ Step 3: Position the Cutter – Place the cutting edge directly on the mark where the wire needs to be cut.

✔ Step 4: Apply Even Pressure – Squeeze steadily to prevent fraying or distortion.

✔ Step 5: File or Sand Edges – Smooth out any rough edges using a metal file or sandpaper.

✅ Tip: When working with hard wires, wear safety glasses to protect against flying debris.

How to Shape Wire for Custom Designs

Bending and shaping wire requires a steady hand and the right approach. Whether creating loops for jewellery, bends for electrical installations, or precise angles for industrial applications, technique matters.

Step-by-Step Guide to Shaping Wire

✔ Step 1: Mark Your Bend Points – Use a ruler and marker to outline where the bends should go.

✔ Step 2: Choose the Right Tool – Pliers work for small bends; mandrels help shape larger curves.

✔ Step 3: Apply Even Pressure – Bend gradually to avoid weakening the wire.

✔ Step 4: Check Angles – Use a protractor or jig for precise bends.

✔ Step 5: Harden the Wire (If Needed) – Use a hammer or rolling mill to strengthen soft wires.

✅ Tip: For springy materials like stainless steel, annealing (gentle heating) before shaping can improve flexibility.

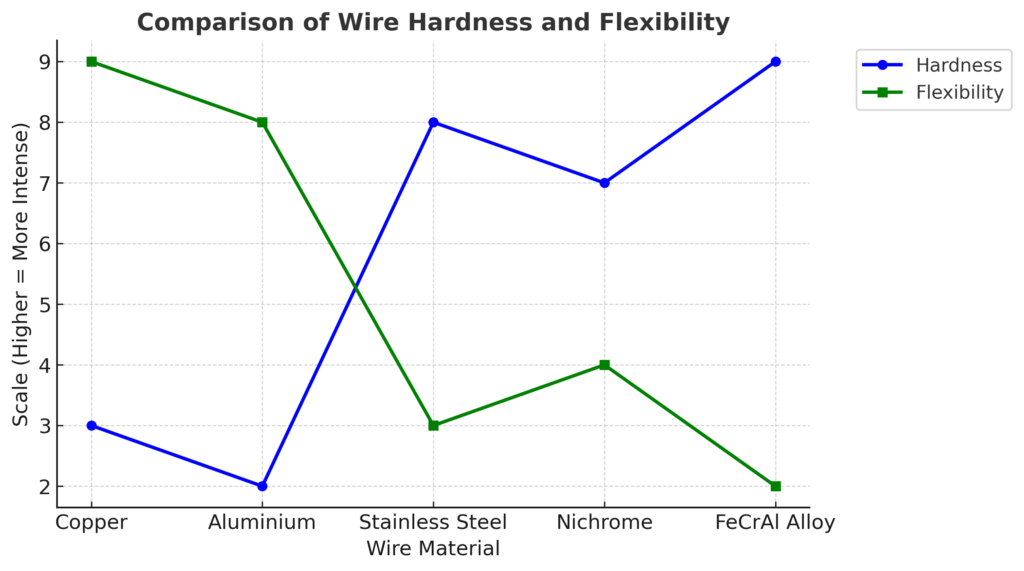

Graph: Wire Hardness vs. Flexibility

A graph illustrating wire hardness versus flexibility can help users understand which materials are easier to cut and shape.

(Graph comparing copper, aluminium, stainless steel, and nichrome wire in terms of hardness and bendability.)

✅ Key Insight: Copper and aluminium are the easiest to shape, while stainless steel and FeCrAl require more force.

Common Mistakes to Avoid When Cutting and Shaping Wire

❌ Using the Wrong Tool – Using standard scissors or improper pliers can damage both the wire and the tool.

❌ Applying Too Much Force – Excessive pressure can cause kinks, weakening the wire.

❌ Ignoring Safety Precautions – Always wear gloves and safety glasses when cutting hard metals.

❌ Not Measuring Properly – Cutting too short or shaping inaccurately leads to wasted material.

❌ Skipping the Finishing Process – Always smooth sharp edges to prevent injury or fraying.

Why Buy Quality Wire from The Crazy Wire Company?

At The Crazy Wire Company, we offer premium wires suitable for cutting and shaping across various applications:

✔ Pure copper and aluminium wire for easy manipulation.

✔ Stainless steel and FeCrAl Wire for high-durability projects.

✔ Nichrome wire for heating elements and specialised crafts.

✔ Fast UK dispatch with expert support for choosing the right wire.

Conclusion: Mastering the Art of Cutting and Shaping Wire

Learning to cut and shape wire effectively ensures high-quality, durable results in any project. By selecting the right tools, techniques, and materials, professionals and hobbyists alike can achieve precision in their work. Whether using copper for electrical projects, stainless steel for structural applications, or nichrome for heating elements, mastering these skills will enhance both functionality and aesthetics.

For premium-quality wires, visit The Crazy Wire Company today!

Shop Now for High-Quality Wire for Your Custom Projects!

We offer also a massive range of stainless steel wire and nichrome wire through our store. Choose the wire that you want to work with and we’ll get spooling.

If you’re interested in learning more about wire, check out our other blog on Everything You Need to Know About Wires.

We are also proud to supply this product on our highly popular eBay store, check us out there too.

Thank you for checking out our site.

- MULTIBUY SAVINGS – ORDER 5 FOR 20% OFF

- FREE UK Delivery For All Orders Over £25

- Immediate Express Dispatch From Stock

- Orders Fulfilled From Warrington, UK

- Tracked Delivery with Order Updates

- 30-Day Unused Returns Accepted