Description

20 AWG KA1 Flat Clapton

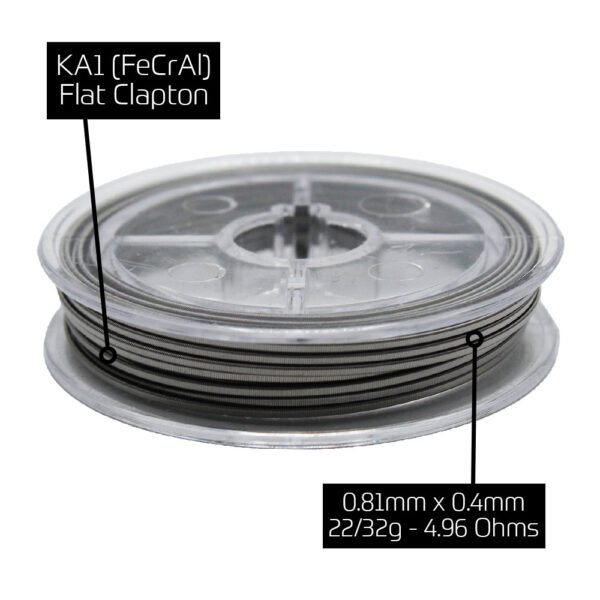

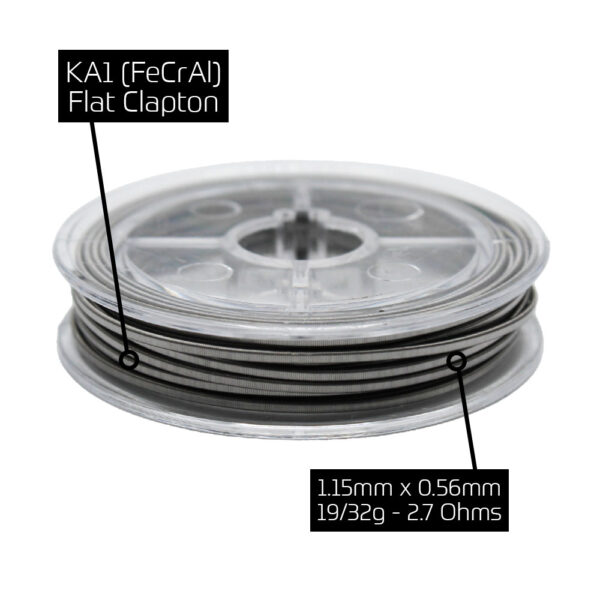

The 20 AWG KA1 Flat Clapton wire, available in a 5-metre spool (15 feet), is a versatile and durable product suitable for various electrical and hobbyist projects. It has a 20 AWG core that is surrounded by a 32 AWG wrap, providing a balance between conductivity and strength. With a resistance of 2.33 Ω/m, it is ideal for applications requiring precise resistance values. In addition to enhancing surface area, the flat design of the wire allows the wire to distribute heat more efficiently. Model-making, jewelry-making, DIY electronics, and model-making using this wire is easy due to its flexibility and ease of handling. With a convenient spool package, it is easy to store and use, making it a practical choice both for enthusiasts and professionals.

About The Product

The details of this product are as follows:

- Spool Length – 5 Metre Spool (15ft)

- Metal – FeCrAl A1 Alloy (K A1)

- Resistance – 2.33 Ω/m

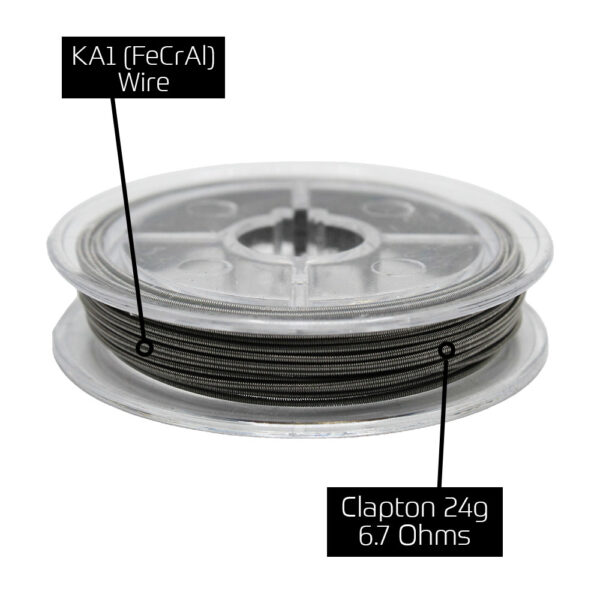

- Coil Type – 20 AWG / 32 AWG Flat Clapton

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

We do not only offer KA1 wire. We also have a huge range of Nichrome and stainless steel wire in immediate stock too.

Ribbon wire and flat wire are stocked for immediate dispatch too.

FAQs About This Product

What Types Of Electrical Projects Are Best Suited For 20 AWG KA1 Flat Clapton Wire?

- DIY Electronics: For building or repairing small electronic devices where specific resistance and heat management are crucial.

- Model Making: Especially in intricate models that require fine, heat-resistant wiring.

- Custom Lighting Projects: Its ability to handle heat effectively makes it suitable for LED installations and custom lighting setups.

- Repair and Modification of Small Appliances: Its strength and flexibility make it a good choice for repairing or modifying small electrical appliances.

- Educational Projects: In educational settings, this wire can be used to teach about electrical circuits, resistance, and heat distribution in a hands-on manner.

- Artistic Installations: For artists working with electronic components, this wire can be used to create interactive or illuminated art pieces.

- Prototyping: Ideal for prototyping electronic circuits that require stable and reliable wiring.

Can The 20 AWG KA1 Flat Clapton Wire Handle Heat Distribution?

Yes, the 20 AWG KA1 Flat Clapton wire is well-suited for handling heat distribution. In comparison with round wires, the flat design maximises the surface area, which allows heat to dissipate more effectively. In applications where maintaining a consistent temperature or managing heat is crucial, this characteristic is particularly valuable.

The wire’s construction and material are made to resist heat, so it’s a good choice for DIY electronics and model making projects that require heat resistance. However, you should always consider the specific needs of your project and ensure that the heat tolerance of the wire matches the requirements.

Check out our blog expanding on the difference between Clapton and Flapton coil wires. This is an extremely detailed article, which we hope will provide much insight into the subject.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.