Description

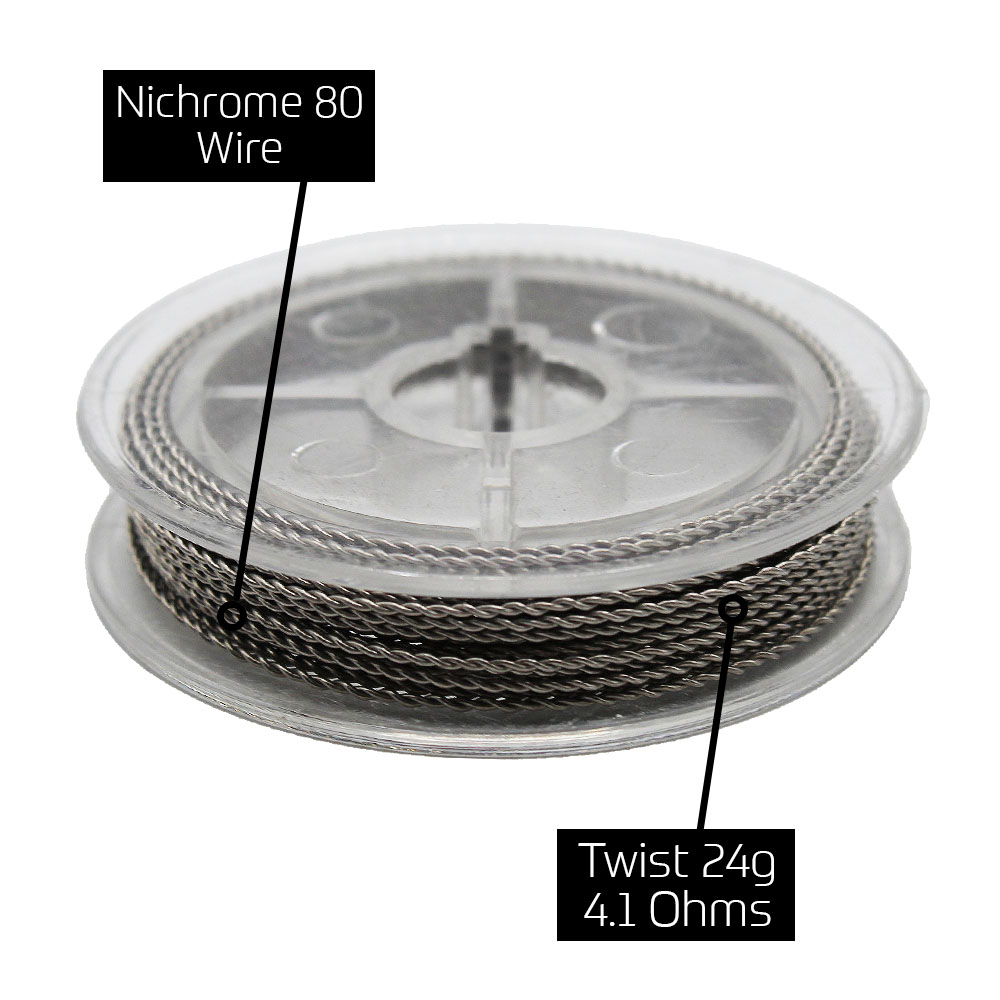

Ni80 Twist 24

The Ni80 Twist 24 is a high-quality resistance wire tailored for diverse applications that demand precision and reliability. Due to its high conductivity and resilience, this wire is made with an alloy containing 80% nickel. 24 AWG x 2 translates to a diameter suitable for a range of applications. One of its main attributes is its resistance value, which stands at 4.10 Ω/m, enabling users to achieve specific resistance requirements in their builds. The Ni80 Twist 24 comes on a 5-metre spool, which is approximately 15 feet long and is efficiently wound. Its length makes it a practical choice for hobbyists and professionals. When quality and performance are both essential for any project, the Ni80 Twist 24 wire delivers both. A consistent output and minimal variance are key for accurate tasks. Further, since the wire is twisted, it provides additional mechanical strength and uniformity.

About The Product

The details of this product are as follows:

- Spool Length – 5 Metre Spool (15ft)

- Metal – Ni80 Nichrome NiCr80/20

- Resistance – 4.10 Ω/m

- Coil Type – Twist 24 (24 AWG x 2)

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

We do not only offer Ni80 wire. We also have a huge range of KA1 and stainless steel wire in immediate stock too.

Ribbon wire and flat wire are stocked for immediate dispatch too.

FAQs About This Wire

Are There Precautions To Take When Handling Ni80 Twist 24?

- Wear Appropriate Protection: It’s advisable to wear gloves to prevent potential skin irritation, especially if you have nickel sensitivity. Additionally, using gloves can help avoid leaving oils or residues on the wire which can affect its performance.

- Avoid Overstretching: When manipulating the wire, ensure not to overstretch it. Overstretching can alter its resistance and weaken the wire.

- Use Proper Tools: Always use the appropriate tools for cutting and handling the wire. Using blunt or inappropriate tools can damage the wire or create uneven cuts.

- Work in Well-Ventilated Areas: If you’re heating the wire for any reason, it’s important to work in a well-ventilated space. When nickel-based wires are heated, they can release fumes that should not be inhaled.

- Check for Defects: Before using, always inspect the wire for any defects, kinks, or inconsistencies that could affect its performance.

- Storage: After usage, store the wire in a cool, dry place, preferably in its original spool to prevent it from tangling or getting damaged.

- Know the Specs: Always be aware of the wire’s specifications, especially its resistance. This helps ensure that you’re using it appropriately for your intended application.

- Avoid Mixing with Other Metals: If you’re using the wire in electrical applications, ensure not to mix it with wires of different metals or resistance levels unless you’re certain of the outcome. This can lead to unpredictable results.

- Educate Yourself: If you’re new to working with resistance wires, take time to educate yourself about their properties and uses. The more you know, the safer and more effective your work will be.

What Is The Best Way To Measure And Cut Ni80 Twist 24?

When working with Ni80 Twist 24 wire, precision in measurement and cutting is crucial. Start by laying the wire flat against a ruler or measuring tape in a well-lit workspace, and making sure it is stretched gently for accuracy. Once you’ve determined the desired length, mark the spot with a fine-tipped marker. To make a clean cut at the marked location, use wire cutters designed for resistance wire. If there are any irregularities in the wire ends, smooth them with fine-grit sandpaper or a smoothing tool after cutting. During the cutting process, always wear safety glasses to protect against any flying wire fragments as well as storing any unused portion properly to prevent tangling.

Check out our blog expanding on the difference between Clapton and Flapton coil wires. This is an extremely detailed article, which we hope will provide much insight into the subject.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

Reviews

There are no reviews yet.