Description

0.45mm KA1 (FeCrAl A1) Round Wire

The Crazy Wire Company are best known and long established as Europe’s preferred suppliers of top quality 0.45mm KA1 (FeCrAl A1) round wire. We have enormous stock levels at all times as we use this wire to weave our mesh products.

0.45mm KA1 is a type of wire used for resistance heating applications. The “A1” designation signifies that it is the original, standard grade of Kanthal wire. The 0.45mm diameter makes it suitable for use in heating elements that require moderate amounts of power, as its larger diameter allows it to handle higher currents than thinner wires.

The use of 0.45mm KA1 wire can result in slower heating and cooling times compared to thinner wire, but it can also handle higher power levels, which can be beneficial for heating elements that need to heat up quickly or generate large amounts of heat. Additionally, its larger diameter makes it less prone to breakage compared to thinner wire, which can be important in applications where the heating element is subjected to mechanical stress.

As with any resistance heating wire, it’s important to consider the electrical properties of 0.45mm KA1 wire, such as its resistance, maximum operating temperature, and current handling capabilities, to ensure it is suitable for the specific application.

Key product details:

- C = Min – 0% Max – 0.08%

- Si = Min – 0% Max – 0.7%

- Mn = Min – 0% Max – 0.4%

- Cr = Min – 20.5% Max – 23.5%

- Al = Nominal Comp – 5.8% – Min – 0% – Max – 0%

- Fe = Balance

- Diameter – 0.45mm (450 Micron – 25 AWG)

- Ohms/ft – 8.93

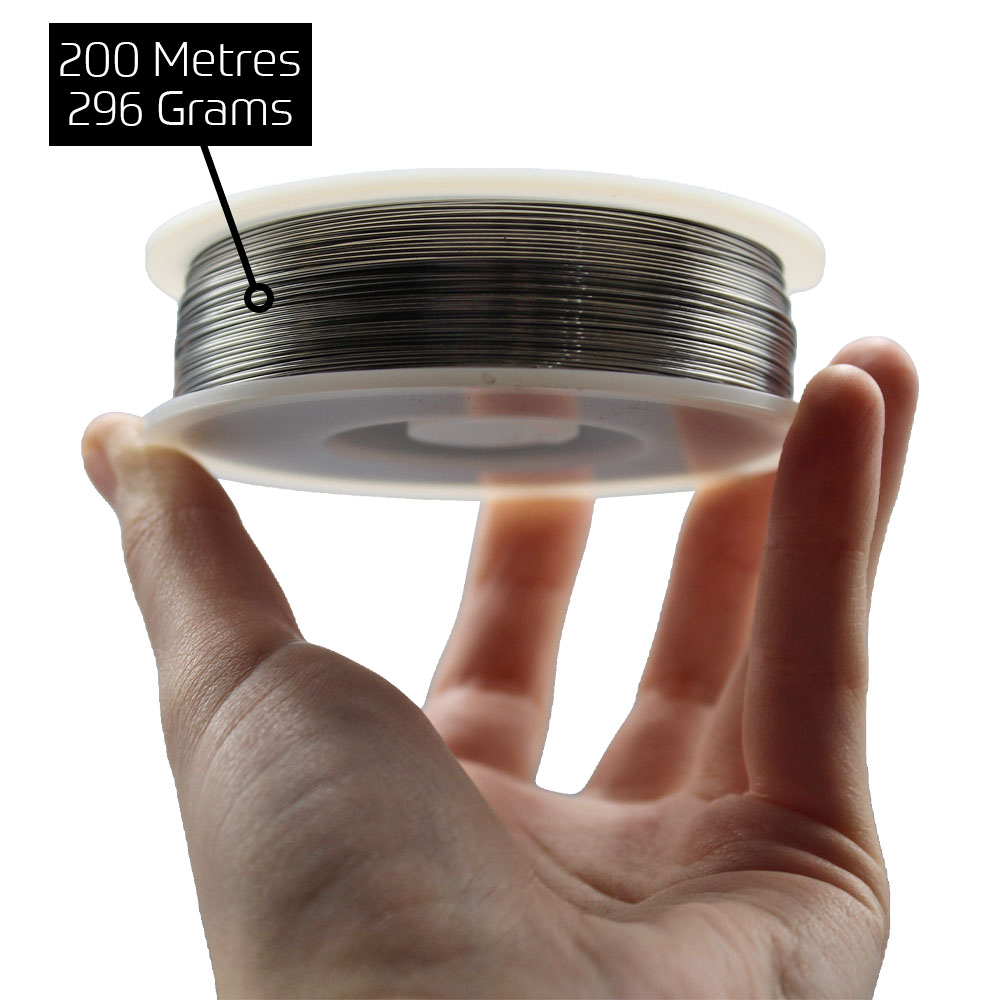

- Spool Size –296g (Approx. 200 Metres)

Available KA1 Options:

- 1.15mm (17 AWG) – 1.35 ohms/m

- 1.02mm (18 AWG) – 1.77 ohms/m

- 0.9mm (19 AWG) – 2.15 ohms/m

- 0.8mm (20 AWG) – 2.84 ohms/m

- 0.7mm (21 AWG) – 3.58 ohms/m

- 0.6mm (22 AWG) – 4.94 ohms/m

- 0.65mm (22 AWG) – 4.26 ohms/m

- 0.64mm (22 AWG)

- 0.5mm (24 AWG) – 7.11 ohms/m

- 0.55mm x 0.1mm – 26.05 ohms/m

- 0.55mm (23 AWG) – 5.96 ohms/m

- 0.4mm (26 AWG) – 11.46 ohms/m

- 0.48mm (25 AWG) – 7.79 ohms/m

- 0.45mm (25 AWG) – 8.93 ohms/m

- 0.42mm (26 AWG) – 10.6 ohms/m

- 0.3mm (29 AWG) -19.89 ohms/m

- 0.38mm (27 AWG) – 12.79 ohms/m

- 0.37mm (27 AWG) – 13.26 ohms/m

- 0.35mm (27 AWG) – 14.69 ohms/m

- 0.34mm (28 AWG) -15.15 ohms/m

- 0.32mm (28 AWG) -17.46 ohms/m

- 0.2mm (32 AWG) – 46.11 ohms/m

- 0.28mm (30 AWG) – 22.75 ohms/m

- 0.27mm (30 AWG) – 24.86 ohms/m

- 0.25mm (30 AWG) – 29.29 ohms/m

- 0.23mm (31 AWG) – 34.36 ohms/m

- 0.21mm (32 AWG) – 40.44 ohms/m

- 0.1mm x 0.2mm – 71.83 ohms/m

- 0.1mm (38 AWG)

- 0.18mm (33 AWG) – 56.98 ohms/m

- 0.17mm (34 AWG) – 62.57 ohms/m

- 0.15mm (34 AWG) – 82.52 ohms/m

- 0.13mm (36 AWG) – 107.87 Ohms/m

- 0.12mm (36 AWG)

- 0.09mm (39 AWG) – 228.40 ohms/m

- 0.08mm (40 AWG)

- 0.07mm (41 AWG)

- 0.06mm (42 AWG) – 496 ohms/m

- 0.05mm (44 AWG) – 577 ohms/m

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

We do not only offer KA1 round wire. We also have a huge range of Ni80 and stainless steel round wire in immediate stock too.

Ribbon wire and flat wire are stocked for immediate dispatch too.

FAQs About This Wire

Does KA1 Rust?

KA1 wire is resistant to rust, but it is not completely immune to corrosion. The FeCrAl alloys used in KA1 wire contain chromium, which provides excellent resistance to high-temperature oxidation and corrosion. This makes it suitable for use in high-temperature heating applications where it is exposed to high temperatures and potentially corrosive environments.

However, it’s important to note that no material is completely immune to corrosion, and the resistance of KA1 wire to rust and corrosion will depend on a number of factors, including the specific conditions it is exposed to, such as temperature, humidity, and the presence of corrosive chemicals or gases. To maximize the resistance of KA1 wire to rust and corrosion, it’s important to store and use it properly and to follow the manufacturer’s recommendations for its use and maintenance.

How Is KA1 Made?

KA1 wire is made by melting high-purity iron (Fe), chromium (Cr), and aluminium (Al) together to form an alloy. This alloy is then cast into rod form, which is further processed to produce wire. The exact composition of the alloy will vary depending on the specific type of KA1 wire being produced, but in general, the FeCrAl alloys used in KA1 wire contain between 12% and 30% chromium and between 2% and 7% aluminium.

The processing of the KA1 wire involves a series of steps that are designed to produce a wire with the desired electrical resistance, mechanical strength, and resistance to high-temperature oxidation and corrosion. This typically includes steps such as hot rolling, annealing, and drawing the wire to its final diameter. After the wire has been produced, it is often coated with an insulating material, such as a ceramic or a polymer, to help prevent electrical shorts and to protect the wire from damage during handling and installation

How Is Round Wire Made?

Round wire is made by a process called drawing. This process involves starting with a rod of metal, usually made from a high-purity alloy such as steel, stainless steel, or an electrical resistance alloy like KA1. The rod is then heated to a temperature where it becomes pliable, and it is pulled through a series of progressively smaller dies to reduce its diameter to the desired size. This process of pulling the metal through the dies is known as drawing.

The draw process can be repeated multiple times to produce wire with even smaller diameters, and the wire can be annealed between each draw to help maintain its mechanical strength and electrical resistance. After the wire has been drawn to its final diameter, it may be coated with an insulating material or treated to improve its resistance to corrosion or oxidation.

The specific steps involved in making round wire can vary depending on the material being used and the desired properties of the wire, but in general, the process involves the following steps:

- Rod production: The rod is produced by casting the metal in a mould or by forging it.

- Annealing: The rod is heated to a temperature where it becomes pliable, and then it is cooled slowly to relieve any stresses that may have been introduced during casting or forging.

- Drawing: The rod is pulled through a series of progressively smaller dies to reduce its diameter.

- Annealing (optional): The wire may be annealed again to help maintain its mechanical strength and electrical resistance.

- Coating (optional): The wire may be coated with an insulating material or treated to improve its resistance to corrosion or oxidation.

Overall, the process of making round wire is a carefully controlled and highly specialized process that involves a number of steps designed to produce wire with the desired properties for a specific application.

What Is KA1 Wire Used For?

KA1 wire is primarily used for high-temperature heating applications, such as heating elements in electric furnaces, ovens, and kilns, as well as for making resistance heating wire for industrial processes, such as annealing and sintering. The high electrical resistance of the FeCrAl alloys used in KA1 wire, combined with its excellent resistance to high-temperature oxidation and corrosion, makes it well-suited for these applications.

KA1 wire is also used in other high-temperature applications, such as heating elements in heat treatment furnaces and as a heating element in electrical discharge machines (EDMs) used in metalworking and manufacturing.

Check out our blog ‘Everything that you need to know about wires‘ for more information on KA1 wire in general. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.