Description

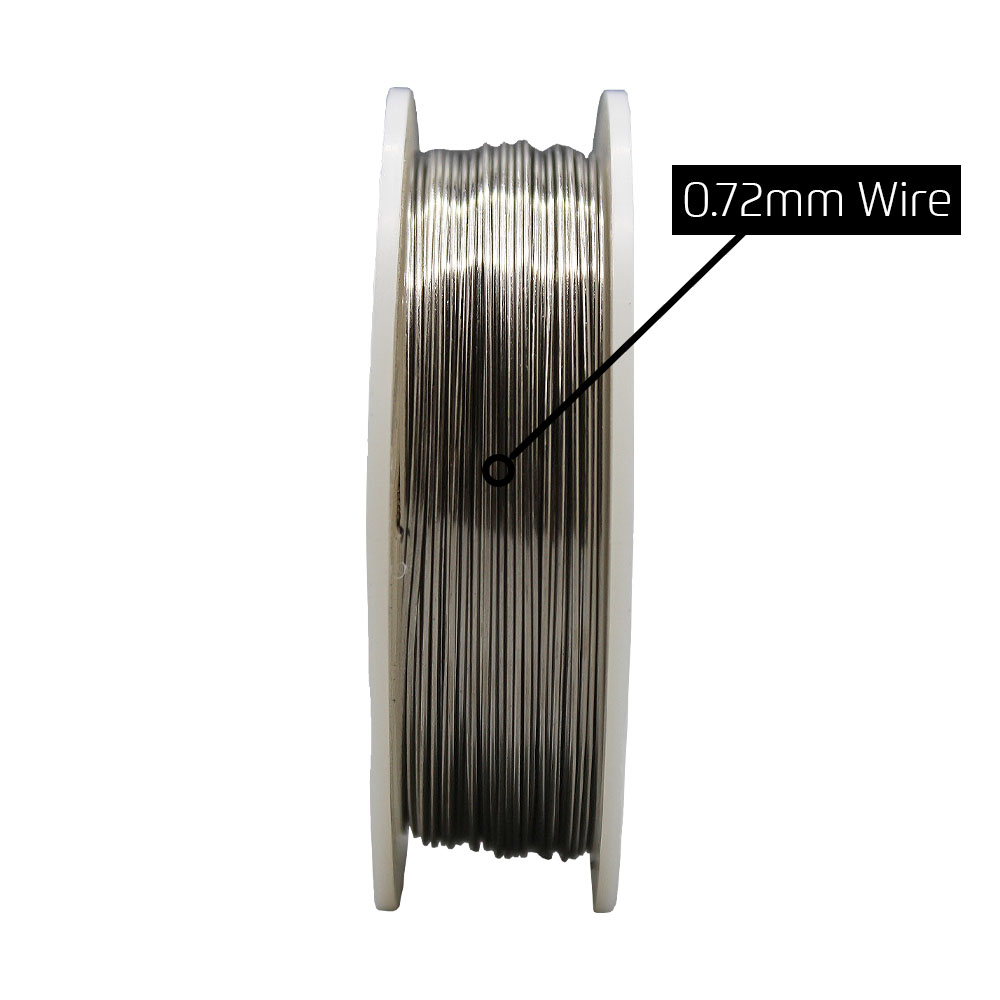

Ni90 Chrome Wire

The Crazy Wire Company is best know as suppliers of top-quality Ni90 chrome wire. We have enormous stock levels at all times, as we use this wire to weave our specialist-grade woven mesh products. Our brilliant staff are experts in producing our spools of round wire on our 6 rapid action winding machines. All spools are produced to carry a little extra length to make up for any waste when handling the product.

The ni90 chrome wire, measuring at 0.72mm (21 AWG), is a premium nichrome alloy known for its exceptional electrical conductivity and consistent resistive properties. Because of its inherent resistance to oxidation and corrosion, this metal is extremely durable, especially when exposed to high temperatures. For appliances such as toasters and hairdryers, as well as specialised electronic applications, this wire is a good choice due to its quick heating ability and temperature stability. The versatility of this material extends to crafts, where its malleability is appreciated, as well as sectors like aerospace and automotive that require precise performance. There are numerous industries in which ni90 chrome wire can be used, and its reliability and performance are unmatched.

Key product details:

- Diameter – 0.72mm (720 Micron – 21 AWG)

- Ohms/m –

- Technical Specification:

- Ni – Rest

- Cr – 10.0

- Fe – <1.0

- Magnetic Properties – Nonmagnetic

- Electrical resistance is high

- Corrosion resistance is high

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

We do not only offer Ni90 round wire. We also have a huge range of KA1 and stainless steel round wire in immediate stock too.

Ribbon wire and flat wire are stocked for immediate dispatch too.

FAQs About This Wire

Can Ni90 Chrome Wire Be Used For Arts and Crafts?

Yes, Ni90 chrome wire can be used for arts and crafts. The malleability of this material makes it a popular choice among artisans and crafters. Jewelry, sculptures, and other decorative items can be created with the wire’s flexibility. Moreover, its durability and resistance to oxidation ensure that crafted pieces remain attractive for a long time. To ensure the best results when working with wire, crafters should use appropriate tools and safety precautions.

Is Ni90 Chrome Wire Safe For Use In Medical Devices?

Chrome Ni90 wire has a number of properties that make it suitable for certain applications, including its ability to resist oxidation and electrical conductivity. When it comes to medical devices, materials are chosen carefully to ensure patient safety according to rigorous standards and criteria. A medical device containing Ni90 chrome wire would have to undergo thorough biocompatibility testing in order to ensure that it will not cause any adverse reactions when introduced to the human body. Manufacturers also consider corrosion resistance, strength, and fatigue resistance when creating medical devices. Choosing materials for medical applications requires consulting experts and adhering to specific industry standards and regulations. You should always ensure any material, including Ni90 chrome wire, is approved for medical use.

Can Ni90 Chrome Wire Be Painted Or Coated?

Yes, Ni90 chrome wire can be painted or coated, but there are considerations to keep in mind:

- Preparation: Before painting or coating, it’s essential to ensure the wire is clean and free from oils, grease, or oxidation. This can be achieved using isopropyl alcohol or another suitable solvent.

- Adhesion: Not all paints or coatings will adhere well to metals without a proper primer. It’s advisable to use a metal primer to increase paint adhesion.

- Type of Paint/Coating: High-temperature-resistant paint or coatings are recommended if the wire will be heated, as standard paints can degrade or emit fumes under high temperatures.

- Application: Spraying often provides a more even coat than brushing, especially for thin wires. Multiple thin layers usually work better than one thick layer.

- Curing: Depending on the paint or coating used, it might need a curing process, either through air-drying or baking.

- Performance Impact: Painting or coating can affect the wire’s thermal and electrical properties. If the wire is to be used in an application where these properties are critical, it’s essential to account for any potential changes.

Always refer to the specific paint or coating manufacturer’s guidelines for best results. If the wire’s performance characteristics are essential for your application, it’s advisable to test the coated wire under intended conditions to ensure it meets the required standards.

Can Ni90 Chrome Wire Be Used In Underwater Applications?

Ni90 chrome wire can be used in underwater applications, but several factors need to be considered:

- Corrosion Resistance: While Ni90 chrome wire has good resistance to oxidation and corrosion in many environments, prolonged exposure to water, especially saltwater, can accelerate corrosion. It’s important to evaluate the type of water (freshwater, saltwater, or chemically treated water) the wire will be exposed to.

- Insulation: If the wire is to be used underwater, it’s crucial to have an appropriate insulation or coating that is waterproof and resists degradation from water exposure. This ensures that the wire maintains its electrical properties and is protected from potential short circuits.

- Pressure and Depth: The deeper underwater the wire is used, the higher the pressure it will be exposed to. It’s important to ensure that any coatings, insulation, or encasements can withstand the pressures at the intended depth.

- Thermal Conductivity: Water has a cooling effect, which can impact the wire’s ability to heat up or maintain specific temperatures if used as a heating element. This needs to be taken into account for applications that rely on the wire’s heating properties.

- Maintenance and Inspection: Regular checks are vital for underwater applications to ensure there’s no damage, corrosion, or other issues with the wire.

While Ni90 chrome wire can be adapted for underwater use, it’s essential to use it within the right parameters and considerations.

The Crazy Wire Company is a leading UK based supplier of nichrome, fecral, and stainless steel wires. We specialise in rapid delivery to any location around the country. Our factory is located in Warrington, which is the historic home of the UK’s wire industry.

Check out our blog ‘Everything That You Need To Know About Wire‘ for more information on resistance wire in general. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

Reviews

There are no reviews yet.