When it comes to building custom heating elements, choosing the right material is essential. Among the many options available, Ni80 wire—an alloy made from 80% nickel and 20% chromium—has become a popular choice for hobbyists, engineers, and makers alike. But is it really the best option for DIY heating projects?

At The Crazy Wire Company, we specialise in high-quality wire products tailored for heating, electrical, and structural applications. This guide explores whether Ni80 wire is suitable for DIY heating elements by examining its properties, benefits, and limitations.

What is Ni80 Wire?

Ni80 wire, often referred to as nichrome 80/20, is an alloy composed primarily of nickel (80%) and chromium (20%). It is well known for its high electrical resistance and ability to withstand extreme temperatures.

Key Characteristics of Ni80 Wire

✔ High Melting Point – Operates safely in temperatures up to 1,200°C.

✔ Oxidation Resistance – Maintains performance in air-exposed environments.

✔ Consistent Electrical Resistance – Ideal for precise heating control.

✔ Durability – Long lifespan even with repeated heating and cooling cycles.

✔ Low Thermal Expansion – Retains shape and form when exposed to high temperatures.

These properties make Ni80 wire a strong candidate for heating elements used in both industrial and DIY projects.

Why Use Ni80 Wire in DIY Heating Projects?

Many hobbyists and professionals prefer Ni80 wire because it offers a balanced combination of resistance, durability, and heat tolerance.

Top Benefits for DIY Use

Predictable Heating Behaviour – Maintains stable resistance when current is applied.

Easy to Work With – Can be bent and shaped without breaking.

Widely Available – Accessible in various gauges and spool sizes.

Safe for Home Use – Operates efficiently within safe voltage and current limits.

✅ Tip: Always calculate resistance and current needs before integrating Ni80 into a circuit.

Common Applications of Ni80 Wire in DIY Heating

From crafting tools to prototyping gadgets, Ni80 wire is commonly used in:

Foam cutters – Straight segments heat evenly and cut cleanly.

Plastic bending tools – Applies steady, localised heat.

Home-built soldering irons – Forms basic heating coils for light-duty soldering.

Small space heaters – Low-power solutions for tiny enclosures.

Though widely used, certain safety precautions and design limitations should still be considered.

Limitations of Ni80 Wire

While Ni80 wire is versatile, it’s not suitable for every situation. You should be aware of a few downsides:

❌ Not for High-Wattage Applications – May degrade faster under excessive power loads.

❌ Requires Proper Insulation – Bare wire must not contact flammable or conductive surfaces.

❌ Can Be Brittle After Repeated Use – Prolonged heat cycles may reduce flexibility.

❌ Temperature Regulation is Key – Without thermal control, overheating risks arise.

However, many of these limitations can be mitigated with proper circuit design and protective housing.

How to Use Ni80 Wire Safely in DIY Heating

To get the most from your Ni80 wire, follow best practices for handling and installation:

Safety Guidelines

✔ Measure Resistance Carefully – Use Ohm’s Law to determine wire length and power draw.

✔ Use Heat-Resistant Insulation – Prevents damage and protects nearby components.

✔ Ensure Ventilation – Avoid confined, sealed setups.

✔ Secure Wire Properly – Loose coils or unstable mounts pose safety risks.

✔ Avoid Direct Skin Contact When Powered – High surface temperatures can cause burns.

✅ Tip: Start with lower voltages and work upward gradually when testing.

Alternatives to Ni80 Wire for Heating Elements

Although Ni80 wire is excellent for many projects, alternatives may suit different needs:

| Wire Type | Composition | Max Temp | Best Use Case |

|---|---|---|---|

| FeCrAl | Iron-Chromium-Aluminium | ~1,400°C | High-temp industrial heating |

| Nichrome 60 (NiCr 60/15) | Nickel-Chromium | ~1,100°C | Mid-range temperature needs |

| Stainless Steel Wire | Iron-Chromium-Nickel | ~870°C | General heating and support wiring |

| Copper Wire | Pure Copper | ~200°C | Not for heating, excellent for conductivity |

✅ Tip: For long-term, high-temp use, FeCrAl may be more suitable than Ni80 wire.

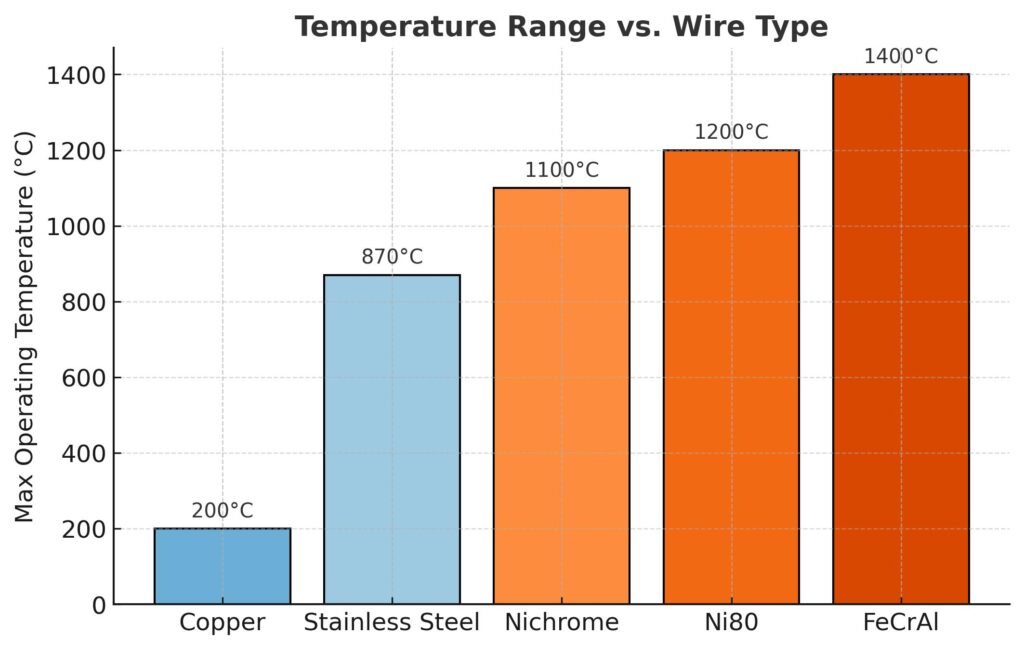

Graph: Temperature Range vs. Wire Type

A visual comparison of the maximum operating temperatures of different heating wires illustrates where Ni80 wire fits in.

✅ Key Insight: Ni80 wire handles most DIY heating needs but is outperformed by FeCrAl in extreme environments.

Why Choose The Crazy Wire Company for Ni80 Wire?

At The Crazy Wire Company, we offer:

✔ High-purity Ni80 wire in various diameters and spool sizes.

✔ Custom-cut lengths to match DIY project requirements.

✔ Expert advice on heat-resistant materials and safe use.

✔ Fast UK dispatch with dedicated support for makers and engineers.

Conclusion: Is Ni80 Wire Right for Your DIY Heating Element?

If you’re designing a compact, reliable heating element, Ni80 wire is an excellent choice. Its consistent performance, easy handling, and high resistance make it ideal for hobbyists and light industrial use. However, ensure proper safety measures and consider alternatives like FeCrAl for extreme applications.

Explore the best Ni80 wire options now at The Crazy Wire Company.

Order Today and Power Up Your DIY Heating Projects!

please could i have a 130 description meta description for this blog please

We offer also a massive range of stainless steel wire and nichrome wire through our store. Choose the wire that you want to work with and we’ll get spooling.

If you’re interested in learning more about wire, check out our other blog on Everything You Need to Know About Wires.

We are also proud to supply this product on our highly popular eBay store, check us out there too.

Thank you for checking out our site.

- MULTIBUY SAVINGS – ORDER 5 FOR 20% OFF

- FREE UK Delivery For All Orders Over £25

- Immediate Express Dispatch From Stock

- Orders Fulfilled From Warrington, UK

- Tracked Delivery with Order Updates

- 30-Day Unused Returns Accepted