Choosing the right wire is crucial for high-performance heating elements and resistors.

A question that we recently received was: “What Are The Electrical Properties Of Flat FeCrAl A1 Ribbon Wire?”

The goal isn’t just to understand the material’s capabilities, but also to leverage its unique properties for specialised electrical applications.

Flat FeCrAl A1 ribbon wire stands out in the field of electrical engineering because of its heat resistance and durability. The purpose of this article is to shed light on the electrical properties that make FeCrAl A1 ribbon wire a material of choice for applications requiring precise heat management.

Let’s get into it…

What is FeCrAl A1 Ribbon Wire?

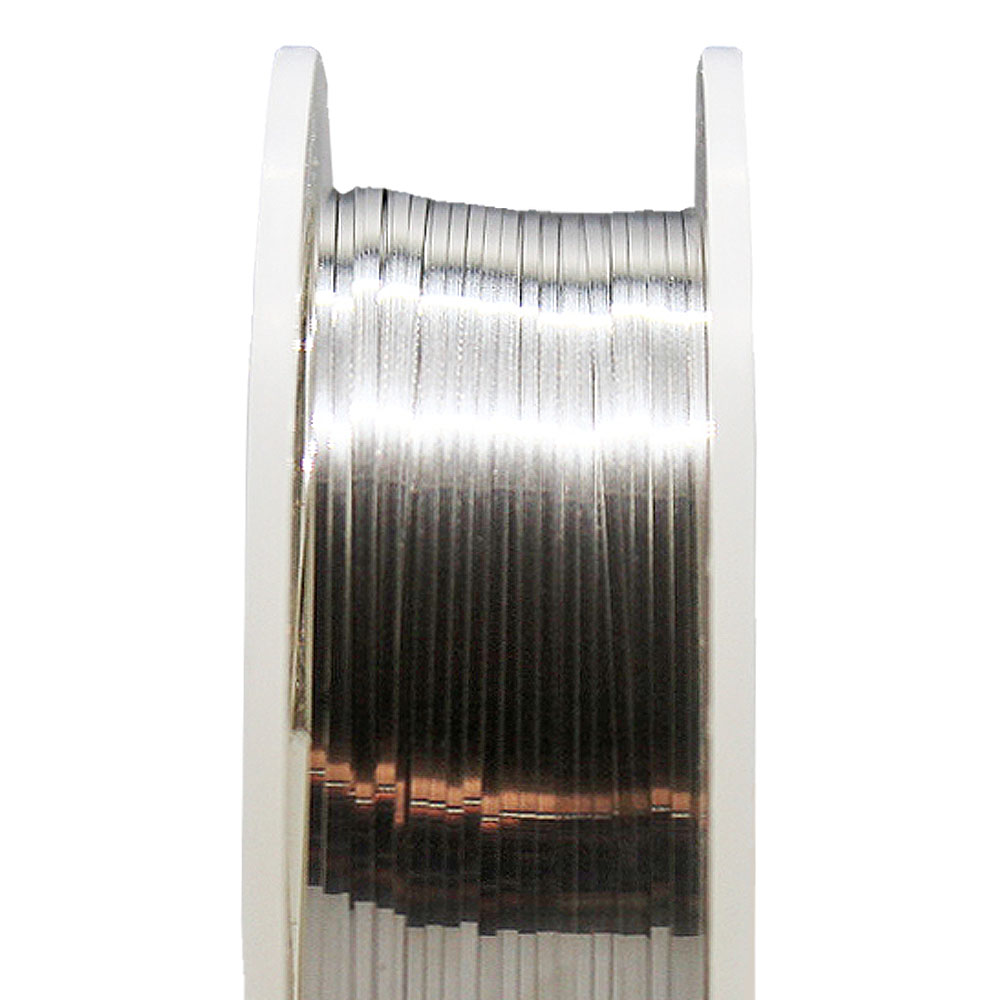

In high-temperature environments, FeCrAl A1 ribbon wire offers superior performance. FeCrAl is typically composed of iron (Fe), chromium (Cr), and aluminum (Al), with ‘A1’ denoting a specific composition optimised for electrical and thermal properties. In contrast to traditional cylindrical wire forms, ribbons have a flat, wide profile.

Ribbon wires have several advantages over round wires due to their flat geometry. Heat is transferred more efficiently to the surrounding environment due to its larger surface area. In applications such as surface heating elements, where even distribution of heat is crucial, this is especially useful. The increased surface area of the ribbon allows for a faster thermal response, making it ideal for precision heating tasks because it allows for more efficient electrical heating.

Electrical Conductivity of FeCrAl A1

The electrical conductivity of FeCrAl A1 is one of its defining characteristics. Despite not conducting electricity as well as metals like copper, it is highly suitable for use as a heating element due to its resistance. A key attribute of this material is its resistivity, which enables it to convert electrical energy into heat efficiently.

FeCrAl A1’s conductivity is affected by several factors, including its composition and microstructure. When heated, chromium and aluminum contribute to the formation of an alumina layer on the wire’s surface, increasing its electrical resistance. For toasters, kilns, or industrial furnaces, this property is crucial for reaching and maintaining high temperatures.

In comparison with Nichrome, FeCrAl A1 typically offers a higher resistivity and a higher maximum operating temperature. Thus, it is more efficient for applications requiring a large amount of heat to be generated. A flat ribbon shape also influences its conductivity by ensuring a more uniform and direct heat distribution, minimising hotspots and ensuring consistent performance throughout the wire’s length.

Resistance Characteristics of FeCrAl A1

In industrial and commercial applications, FeCrAl A1 is valued for its resistance. As a result of its specific elemental makeup, this material has a higher electrical resistance per unit length than many other metals. The chromium component forms a stable and protective alumina layer upon first heating, which contributes to the wire’s high resistance and excellent oxidation resistance. This effect is enhanced by aluminum in the alloy, which forms a thin but effective barrier against further oxidation, essential to maintaining resistance stability over time.

The ribbon shape of FeCrAl A1 wire affects its resistance properties. Ribbon wires have a flat surface, which increases their contact area with the environment. Increasing the contact area allows for more efficient heat dissipation, which prevents overheating and maintains the wire’s resistance characteristics under normal operating conditions. Furthermore, the ribbon wire’s wider profile may reduce the current density for a given power output, resulting in a more uniform heating pattern and less stress on the wire.

Heat Generation and Efficiency

FeCrAl A1 ribbon wire is remarkably efficient at generating heat. A flat profile allows for rapid thermal response times and uniform heat distribution, essential in applications requiring precise temperature control. Due to the ribbon’s broader surface area, heat is evenly dispersed, reducing the chance of hot spots causing material fatigue.

As a result of FeCrAl A1’s efficiency, less power is required to achieve the same heating effect as other materials. The wire’s efficiency not only reduces operating costs but also ensures the sustainability of the systems in which it is used. The uniform heat distribution characteristic of ribbon wires contributes to overall energy efficiency by minimising energy waste.

Durability and Longevity in Electrical Applications

Especially in applications involving cyclic heating, FeCrAl A1 ribbon wire’s durability stands out. A longer service life is ensured by its ability to withstand fluctuations in temperature without affecting resistance significantly. At high temperatures, the alumina layer that forms on the surface protects the wire from deterioration caused by oxidation.

When subjected to continuous electrical currents, FeCrAl A1 demonstrates remarkable durability. Its electrical properties, such as high resistivity and heat tolerance, remain consistent, ensuring reliable performance throughout its lifespan. The FeCrAl A1 alloy’s inherent properties, as well as the ribbon wire’s geometry, together contribute to a durable and long-lasting heating element suitable for a wide range of electrical applications.

Comparative Analysis with Other Alloys

Its optimal balance of electrical resistance and heat tolerance sets FeCrAl A1 ribbon wire apart from alloys such as Nichrome and Kanthal. Nichrome, a nickel-chromium alloy, has a lower maximum operating temperature and a higher electrical conductivity than FeCrAl A1.

In applications requiring lower temperatures and rapid response to electrical current, Nichrome is a better choice. FeCrAl A1 is often the preferred choice for high temperature applications due to its ability to withstand temperatures up to 1400°C without significant oxidation.

In addition to the formation of a protective alumina surface layer upon heating, Kanthal is also made from iron, chromium, and aluminum. While FeCrAl A1 offers a higher resistance, allowing for greater power output and superior longevity due to its excellent oxidation resistance, it is beneficial in some heating applications.

The ribbon shape of FeCrAl A1 wire makes it ideal for surface heating elements that require a large area of coverage and uniform heat distribution. High-temperature industrial furnaces and kilns benefit from its properties as well.

Applications and Case Studies

An array of applications across various industries have found a niche for FeCrAl A1 ribbon wire. The ability to evenly distribute heat in toasters and hair dryers leads to improved appliance performance and user satisfaction. From electric kilns that rely on the wire’s resistance to thermal shock and oxidation to laboratory furnaces that require uniform heating, industrial applications are even more varied.

In aerospace, FeCrAl A1 is utilised in components exposed to high thermal stress, where its stability ensures both safety and functionality. Its value has been demonstrated in sensor and exhaust systems in the automotive industry, where high temperatures and corrosive gases are common. Real-world applications highlight FeCrAl A1’s reliability and the importance of its electrical properties when choosing the alloy.

Maintenance and Handling for Optimal Performance

Maintaining the electrical properties of FeCrAl A1 ribbon wire over its operational life requires adherence to specific handling and maintenance protocols. Proper installation is key; avoiding sharp bends that can stress the wire and ensuring secure connections can prevent premature failure. Regular inspections can identify potential issues like corrosion or physical damage, which can affect the wire’s electrical properties and performance.

Best practices for consistent performance include cleaning the wire with appropriate solutions to remove any contaminants that may lead to increased resistance or potential hot spots. In applications involving repeated heating cycles, allowing the wire to cool gradually can help to maintain its structural integrity and prevent brittleness.

By following these guidelines and leveraging the unique advantages of FeCrAl A1 ribbon wire, industries can ensure that they are making the most of this versatile and robust alloy, thereby achieving optimal performance and extending the life of their heating elements.

FeCrAl A1 ribbon wire is ideal for a variety of high-temperature applications due to its high resistance, excellent heat tolerance, and superior oxidation resistance. Especially in demanding industrial environments, professionals need to understand these properties in order to choose materials that will offer reliability and efficiency. Due to its distinctive geometry, ribbon wires are well suited to applications that require uniform heat distribution and surface contact.

Those looking for a high-performance heating solution can count on The Crazy Wire Company for expert advice and a wide selection of FeCrAl A1 ribbon wire customised to meet their needs. Visit our website to view detailed product specifications and discover our full range of wire options. For guidance and to ensure your next project has the highest quality materials, contact us.

We offer also a massive range of stainless steel wire and nichrome wire through our store. Choose the wire that you want to work with and we’ll get spooling.

If you’re interested in learning more about wire, check out our other blog on Everything You Need to Know About Wires.

We are also proud to supply this product on our highly popular eBay store, check us out there too.

Thank you for checking out our site.

Nichrome Wire Safety: Top Tips for Working Safely

Best Wire for Electronics Projects

Is Ni80 Wire Suitable for DIY Heating Elements

Wire Grades Explained

How Wire Diameter Affects Strength and Flexibility

How to Cut and Shape Wire for Custom Applications

Can Wire Be Used in 3D Printing?

How Wire Composition Affects Conductivity