What You Need To Know About: Foam Cutting Hot Wire

This guide on foam cutting hot wire is part of our series to outline everything that you need to know about our products. We hope that you find it helpful and that it answers any questions that you may have.

We have also written a 1000 word article on cutting wire in general. This may also help you with your search for the right product.

Let’s jump into it…

What do we mean by foam cutting hot wire?

Foam cutting hot wire is a technique used to cut foam materials, such as polystyrene foam or foam rubber, using a heated wire. The wire is heated to a high temperature and then used to melt or vaporise the foam as it cuts through it.

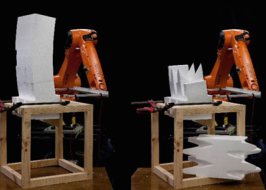

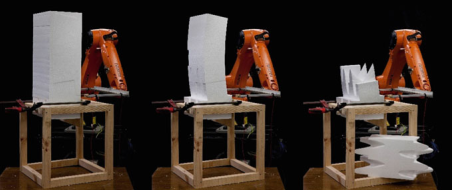

The hot wire can be powered by electricity or by a battery and it can be in different forms, like a straight wire, a bow or a nichrome wire. The wire can be held by hand or mounted on a cutting table or a CNC machine.

This technique is popular for a variety of applications, such as creating foam models, prototypes, and sculptures, as well as for cutting foam for packaging and insulation. The hot wire cutting is a clean and precise method with minimal dust and debris, allowing for intricate and detailed cuts to be made.

When using hot wire foam cutting, it’s important to wear appropriate safety gear, such as gloves and safety glasses, to protect yourself from the heat and potential flying debris. Also, it’s important to keep the wire clean and free of debris, as this can affect the precision and quality of the cut.

Tell me about power supply

Foam cutting hot wire power supply is an equipment that provides the power to heat the wire that is used to cut foam materials. There are different types of power supplies that can be used for foam cutting hot wire, including:

- AC Power Supply: This type of power supply uses alternating current (AC) to heat the wire. It is typically plugged into a wall outlet and can be adjusted to provide different levels of heat.

- DC Power Supply: This type of power supply uses direct current (DC) to heat the wire. It can be powered by batteries or an AC-to-DC converter. This type of power supply is more portable and can be used in places where there is no access to AC power.

- Temperature-controlled Power Supply: This type of power supply uses a temperature sensor to automatically adjust the temperature of the wire to a specific setting. This can be useful for cutting different types of foam materials that require different temperatures for optimal cutting.

- CNC Power Supply: This type of power supply is used when the hot wire is mounted on a CNC machine, and it’s controlled by the machine’s software. It allows for precise cutting, and it can be programmed for different temperatures and speeds.

When selecting a power supply for foam cutting hot wire, it’s important to consider the type of foam that will be cut and the cutting method that will be used, as this will determine the power and temperature requirements of the wire.

What is a foam cutter hot wire knife?

A foam cutter hot wire knife is a tool that uses a heated wire to cut foam materials, such as polystyrene foam or foam rubber. The wire is heated to a high temperature by a power supply and then used to melt or vaporize the foam as it cuts through it.

Hot wire foam cutters come in different forms, like handheld knives or a cutting table with a fixed wire or a CNC machine with a moving wire. Some hot wire knives are designed for general-purpose use, while others are specialised for specific applications, such as cutting insulation, sculpting, or packaging.

A handheld hot wire knife typically has a handle with an electrical heating element inside, and a wire that is stretched between two points, the user holds the handle and guide the wire through the foam.

A cutting table or a CNC machine, on the other hand, have a fixed or moving wire that is controlled by a power supply and software, this allows for more precise cuts, and can cut foam in different shapes and sizes.

When using a foam cutter hot wire knife, it’s important to wear appropriate safety gear, such as gloves and safety glasses, to protect yourself from the heat and potential flying debris. Also, it’s important to keep the wire clean and free of debris, as this can affect the precision and quality of the cut.

DIY?

DIY foam cutting hot wire projects can be a fun and inexpensive way to create custom foam shapes and designs for a variety of applications, such as model-making, sculpture, and packaging.

To create a DIY hot wire foam cutter, you will need a few basic materials and tools:

- A power supply: you can use an AC or DC power supply, depending on your preference and the type of foam you will be cutting. A temperature-controlled power supply can be used for more precise cutting.

- Nichrome wire: this is the wire that will be heated to cut the foam. You can purchase it from a supplier or use an old heating element as a source.

- Wooden or acrylic frame: this will hold the wire in place and can be custom-made according to your needs.

- Wire cutters or pliers: to cut and shape the wire as needed.

- Safety gear: such as gloves and safety glasses to protect yourself from the heat and potential flying debris.

Once you have all the materials and tools ready, you can follow these general steps to create your DIY hot wire foam cutter:

- Build the frame: use the wooden or acrylic frame to hold the wire in place.

- Attach the wire: stretch the nichrome wire between the two points of the frame and secure it in place.

- Connect the power supply: connect the power supply to the wire, making sure that the connections are secure and correct.

- Turn on the power supply: turn on the power supply and adjust the temperature to the desired level.

- Start cutting: use the wire cutters or pliers to guide the wire through the foam, cutting it as desired.

It’s important to note that building a DIY hot wire foam cutter can be a bit challenging, and it’s important to follow proper safety precautions and to use appropriate materials and tools. Also, it’s important to test and adjust the cutter before using it on your final project, to ensure that the cuts are precise and accurate.

What can I cut with it?

Foam cutting hot wire is a technique used to cut foam materials, such as polystyrene foam or foam rubber. The wire is heated to a high temperature and then used to melt or vaporise the foam as it cuts through it.

This technique is commonly used to cut different types of foam materials, including:

- Polystyrene foam: This type of foam is commonly used for insulation, packaging, and model-making. It is lightweight and easy to cut, and it can be used for a variety of projects.

- Styrofoam: This is a brand name of a specific type of expanded polystyrene foam, it’s commonly used in packaging, insulation and model-making, it can also be used for floral arrangements, theatre props, and other craft projects.

- Foam rubber: This type of foam is commonly used for cushions, seat pads, and other types of padding. It is denser and more durable than polystyrene foam and can be cut into various shapes and sizes.

- Ethafoam: This type of foam is a closed-cell, cross-linked polyethylene foam, it’s commonly used for packaging, cushioning and insulation.

- Other types of foam: other types of foam can be cut with a hot wire, as long as the foam is able to reach the temperature needed to vaporise or melt it. However, it’s important to note that each type of foam may have different properties, such as density, thermal conductivity and melting point, which will affect the cutting process and the final result.

It’s important to use the appropriate temperature and cutting speed for the specific type of foam you are working with to ensure that the cuts are precise and accurate. It’s also important to use a wire that is strong enough to cut the foam, but not too thick as it will take longer to heat up.

We think that it pretty much everything that you might need to know about this use for our wire. We offer a massive range of nichrome wire and other nickel materials through our store. Choose the wire that you want to work with and we’ll get spooling.

If you’re interesting in learning more about wire, check out our other blog on Everything You Need to Know About Wires.

We are also proud to supply this product on our highly popular eBay store, check us out there too.

Thank you for checking out our site.

Nichrome Wire Safety: Top Tips for Working Safely

Best Wire for Electronics Projects

Is Ni80 Wire Suitable for DIY Heating Elements

Wire Grades Explained

How Wire Diameter Affects Strength and Flexibility

How to Cut and Shape Wire for Custom Applications

Can Wire Be Used in 3D Printing?

How Wire Composition Affects Conductivity