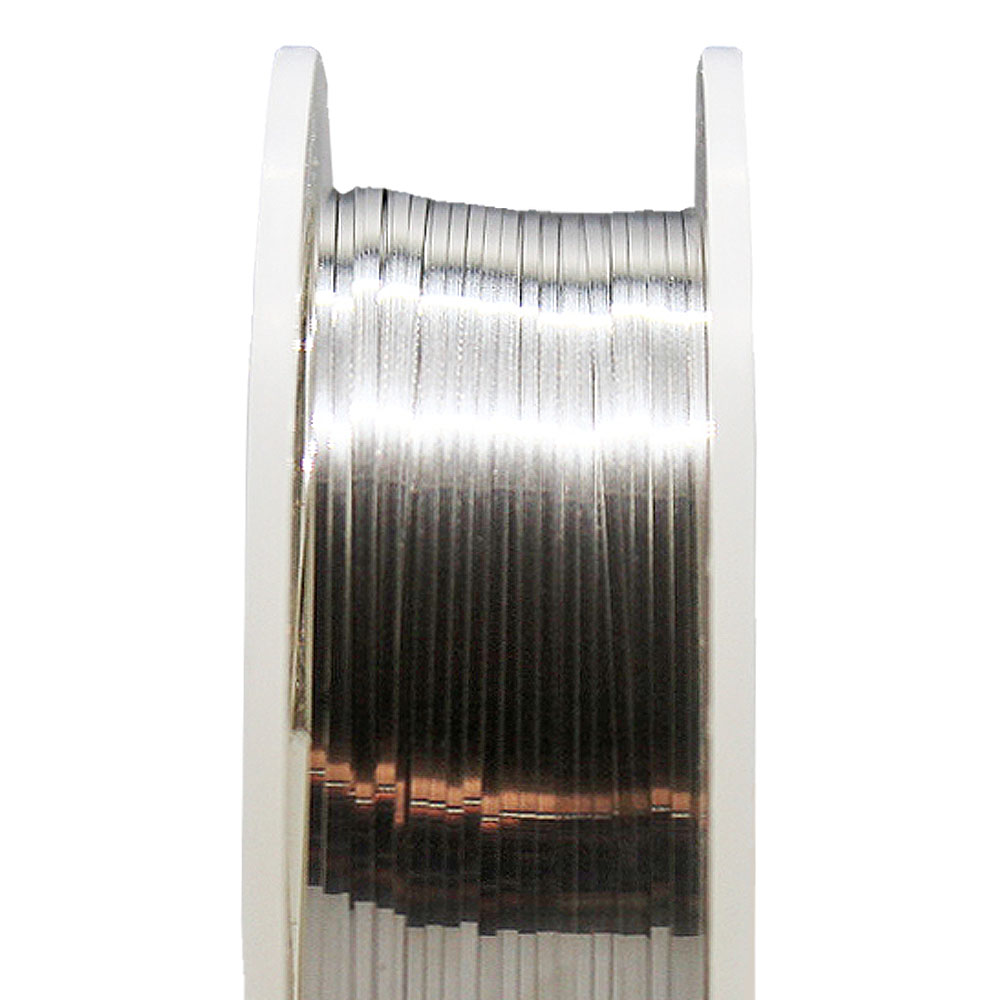

In many engineering and technological domains, the tug of war between different design profiles is a constant. One intriguing dichotomy exists between round and ribbon wire, especially when talking about wires. In the world of wiring, ‘ribbon wire’ has made its mark due to its flat profile, offering some remarkable advantages over its round counterpart. In this blog, we’ll dive deep into the world of ribbon wires and explore the myriad benefits of their flat profile.

1. Increased Surface Area

Perhaps one of the most immediate advantages of ribbon wire is its augmented surface area when compared to round wires. This increase in surface area becomes invaluable in many applications, like heating, where more surface ensures better and more uniform heat distribution. Additionally, in applications requiring electromagnetic interference shielding, a flat profile can often provide more effective coverage.

2. Enhanced Flexibility

While it might seem counterintuitive, ribbon wire can provide better flexibility in specific directions than round wire. Due to its flat profile, ribbon wire can bend effortlessly along its wider dimension, making it a preferable choice in scenarios that require repeated bending or flexing, such as in moving components or hinges.

3. Compactness and Space Saving

Ribbon wire can be tightly packed, offering a significant advantage in applications where space is at a premium. Its uniform flat profile allows for stacking with minimal wasted space between layers, as opposed to round wires which can lead to inefficient use of space due to their circular cross-section. This characteristic is particularly valuable in electronics, where reducing the footprint can lead to more compact and sleek designs.

4. Ease of Identification

Multiple circuits or connections often require different wires. Ribbon wire provides an elegant solution by allowing individual wires to be color-coded or marked more efficiently due to its broader surface. This results in easier identification during installation or troubleshooting, reducing the chances of errors.

5. Improved Signal Integrity

When dealing with data or signal transmission, maintaining signal integrity is paramount. Ribbon wires, especially those used in ribbon cables, maintain consistent spacing between individual conductors, reducing cross-talk and ensuring that signals are transmitted with minimal interference.

6. Simplified Connector Integration

Ribbon wires are tailor-made for use with IDC (Insulation Displacement Connectors). Their flat profile ensures that all wires are aligned and can be simultaneously connected, streamlining the process and minimising connection errors. This can lead to faster assembly times and more reliable connections.

7. Enhanced Heat Dissipation

Heat can be a nemesis for electronic components. The increased surface area of ribbon wire can offer better heat dissipation when compared to round wires. This means that for applications that tend to heat up, ribbon wire can ensure longevity and reduce the risk of overheating.

8. Reduced Skew in Data Transmission

In the world of high-speed data transmissions, even minute differences in wire length can lead to data arriving at different times, an issue known as ‘skew’. Ribbon wires, when used in cables, ensure parallelism and consistent lengths, reducing skew and ensuring synchronised data delivery.

9. Aesthetic Appeal

Although the functional advantages of ribbon wire are plentiful, we can’t ignore the aesthetic aspect. The sleek and flat profile of ribbon wire can be more visually appealing in certain applications. Whether used in jewelry design or visible wiring in transparent devices, ribbon wire can provide a modern and clean look.

10. Durability and Longevity

Due to its design, ribbon wire can often distribute mechanical stresses more evenly across its surface. This can result in a reduced chance of breakage, especially at points of connection or bending, ensuring that the wire lasts longer even under rigorous conditions.

While round wires have been the default choice in many applications for years, the unique advantages offered by ribbon wire are pushing industries to reconsider. Whether you prioritise efficiency, space-saving, reliability, or aesthetics, the flat profile of ribbon wire provides solutions that round wire often cannot.

Incorporating ribbon wire into your next project might just provide the edge you need, be it in product design, electronics, jewelry, or any other application. So the next time you’re faced with a wiring conundrum, remember: sometimes, flat outperforms round!

If you’re interesting in learning more about wire, check out our other blog on Everything You Need to Know About Wires.

We are also proud to supply this product on our highly popular eBay store, check us out there too.

Thank you for checking out our blog.

Nichrome Wire Safety: Top Tips for Working Safely

Best Wire for Electronics Projects

Is Ni80 Wire Suitable for DIY Heating Elements

Wire Grades Explained

How Wire Diameter Affects Strength and Flexibility

How to Cut and Shape Wire for Custom Applications

Can Wire Be Used in 3D Printing?

How Wire Composition Affects Conductivity