Wires are the unheralded heroes of modern technology, playing a crucial role in countless applications across various industries. From transmitting electrical power to forming the backbone of electronic devices and supporting infrastructure projects, wires are indispensable. Their versatility and functionality hinge on various factors, including material composition, gauge, and insulation.

At The Crazy Wire Company, we understand the pivotal role wires play in both everyday and specialised applications. Our extensive range caters to myriad requirements, ensuring that whether you’re a hobbyist, a professional electrician, or an industrial engineer, you find exactly what you need.

We have a huge range of wires available from stock. We hope that the information below can answer some questions that you may have. If you need any further information please send contact us directly or through our social media and we will answer immediately.

Let’s get into it…

Understanding Different Types of Wires

In the vast world of wires, understanding the different types available is key to making the right choice for your specific needs. Each type of wire comes with its unique set of characteristics and advantages, suitable for various applications.

Stainless Steel Wire: The strength and corrosion resistance of stainless steel wire make it ideal for outdoor and harsh environments. Construction, medical instruments, and automotive industries commonly use it.

Copper Wire: Copper wire is widely used in electrical wiring, electronics, and telecommunications due to its excellent electrical conductivity. Additionally, its flexibility makes it ideal for intricate jewelry designs.

Galvanised Steel Wire: This wire is coated with a layer of zinc to provide enhanced corrosion resistance. It’s often used in fencing, netting, and outdoor structures where durability is key.

Other Types: Including aluminum, nickel, and brass wires, each offering unique properties for specialised applications from heating systems to artistic creations.

How Wires Are Made

Wires are typically made by drawing a metal through a series of progressively smaller dies. The process of drawing wire is called wire drawing, and it is used to reduce the diameter and increase the length of the wire.

The wire is pulled through the dies, which are typically made of tungsten carbide or diamond. The wire is lubricated to reduce friction and prevent damage to the wire surface. After the wire has been drawn to the desired size, it may be heat-treated, annealed, or coated with a protective material to improve its properties.

Where Is Wire Made?

Wire is made in a variety of locations around the world, with many countries having their own wire manufacturing industries. Some of the leading producers of wire include China, the United States, Germany, Italy, and Japan.

Wire production can be done in small factories or large industrial plants, depending on the type and quantity of wire being produced.

It is also important to note that wire can be made from a variety of different materials, including copper, aluminium, steel, and brass. The choice of material will depend on the intended use of the wire.

Wire Gauges and Measurement

Wire gauge is a crucial aspect of wire selection, impacting everything from electrical resistance to weight and flexibility. The Standard Wire Gauge (SWG) and American Wire Gauge (AWG) are the most commonly used systems.

SWG and AWG Systems: By understanding these systems, you can choose the right wire diameter for your project. In millimeters or inches, each gauge number corresponds to a specific diameter. We recently published a detailed blog article explaining how SWG relates to mm.

Measuring Wire Gauges: It is essential to accurately measure wire gauge to ensure the wire fits your application, especially in electrical installations, where the wrong gauge can lead to overheating or inefficiency.

Selection Criteria for Wires

Selecting the right wire involves more than just picking the right gauge or material. Consider these factors:

Strength and Flexibility: It may be necessary to use a wire that is robust, yet flexible enough to bend without breaking, depending on the application.

Corrosion Resistance: This is essential for wires exposed to harsh environments.

Application-Specific Requirements: High-temperature resistance in industrial settings and color-coded insulation for easy identification in electrical work.

What Are Wires Used For?

Wires are used for a variety of purposes, including conducting electricity, transmitting data and signals, and providing structural support. They can be made from a variety of materials, such as copper, aluminium, and steel, and can be found in a wide range of applications, including electrical wiring in buildings, power transmission lines, telecommunications systems, and mechanical systems.

Electronics: In the electronics industry, wires are the lifelines of circuitry. Copper wire, valued for its superior conductivity, is often used in PCBs and electronic components.

Construction: Stainless steel and galvanised wires are stalwarts in construction. They offer strength and durability, vital for structural stability.

Jewelry Making: The flexibility and aesthetic appeal of certain wires, like those made of silver or coated copper, make them ideal for jewelry making.

Art and Sculpture: Artists and sculptors often use various wires for structural frameworks or as a medium itself.

What Is Resistance Wire?

A resistance wire is a wire that resists the flow of electrical current. This resistance is due to the properties of the material the wire is made from, such as its composition and cross-sectional area.

The wire may be made from a variety of materials, including copper, nickel, or nickel-chromium alloy. The resistance of the wire can be controlled by adjusting its composition or dimensions.

It is used in many electrical and electronic devices, such as heaters, sensors, and resistors.

Are Wires Heat Resistant?

The heat resistance of a wire depends on the material it is made of. Some materials, such as copper and aluminium, have a relatively low melting point. This means they are not suitable for high-temperature applications.

Other materials, such as nickel and tungsten, have a higher melting point and are more heat resistant.

Additionally, the insulation surrounding the wire can also affect its heat resistance.

Handling and Maintenance Tips

Proper handling and maintenance of wires not only ensure safety but also prolong their life. Here are some best practices:

Proper Storage:To prevent corrosion and damage, store wires in a dry, cool place. Wires should be hung or stored on reels.

Handling Precautions: To avoid kinks and breaks, use appropriate tools when handling wires.

Regular Inspection: Inspect wires regularly for signs of wear, corrosion, or fatigue. Failures can be prevented if problems are detected early.

Correct Usage: Wires should be used according to their specified load and environmental conditions to avoid premature degradation.

How Do I Clean Stainless Steel Wire?

To clean stainless steel, you can use a mixture of warm water and mild detergent. Use a soft cloth or brush to gently scrub the wire, then rinse it thoroughly with clean water and dry it with a soft cloth.

Avoid using abrasive cleaning products or steel wool, as these can scratch the surface of the wire. If the wire is particularly dirty or greasy, you can also try using white vinegar or baking soda as a cleaning agent.

How Do You Produce Your Wire Spools?

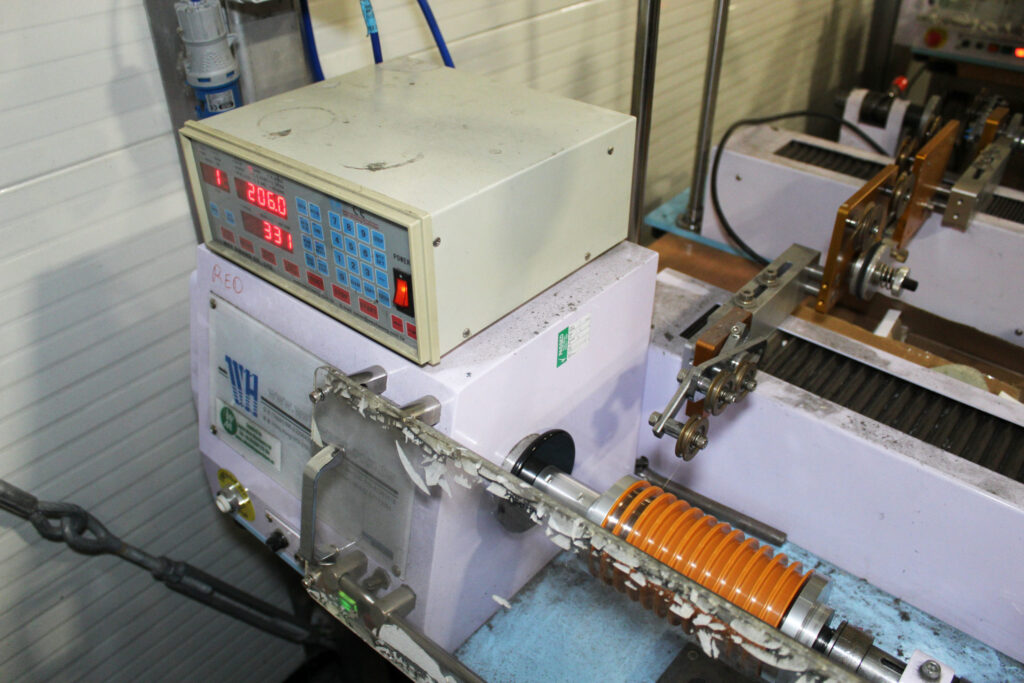

The Crazy Wire Company carry around 6 tonnes of raw wire stocks at all times. This stock is stored on 2 – 5kg masters spools. We know that most do not require so much stock for their needs, so we respool the wire into smaller measurements using one of 6 of our rapid UK made wire winding machines.

We have a small team of expert staff on hand at all times to produce these spools. Lots of care and attention is taken to produce each one.

There are only a handful of companies in the UK who produce spools in this way. Our range, pricing and delivery make us the place to go for all of your wire needs.

The Crazy Wire Company

The Crazy Wire Company is a leading UK based supplier of nickel chrome, fecral, and stainless steel wires. We specialise in rapid delivery to any location around the country. Our factory is located in Warrington, which is the historic home of the UK’s wire industry.

At The Crazy Wire Company, we pride ourselves on offering not just a product but a solution tailored to your specific needs.

- Quality and Variety: Our extensive selection encompasses high-grade wires in various materials and gauges, suitable for a wide array of applications.

- Customisation and Expertise: With our in-depth knowledge and state-of-the-art manufacturing processes, we offer customised solutions that precisely meet your requirements.

- Customer-Centric Approach: We believe in building relationships. Our dedicated customer service team is always ready to assist, whether it’s a query about a product or advice on a project.

With over 150 years experience in the metals industry we are here to help and offer the best possible quality at the best prices. Please get in touch with our sales team if you require any assistance.

We are always happy to help in any way that we can.

Nichrome Wire Safety: Top Tips for Working Safely

Best Wire for Electronics Projects

Is Ni80 Wire Suitable for DIY Heating Elements

Wire Grades Explained

How Wire Diameter Affects Strength and Flexibility

How to Cut and Shape Wire for Custom Applications

Can Wire Be Used in 3D Printing?

How Wire Composition Affects Conductivity