Description

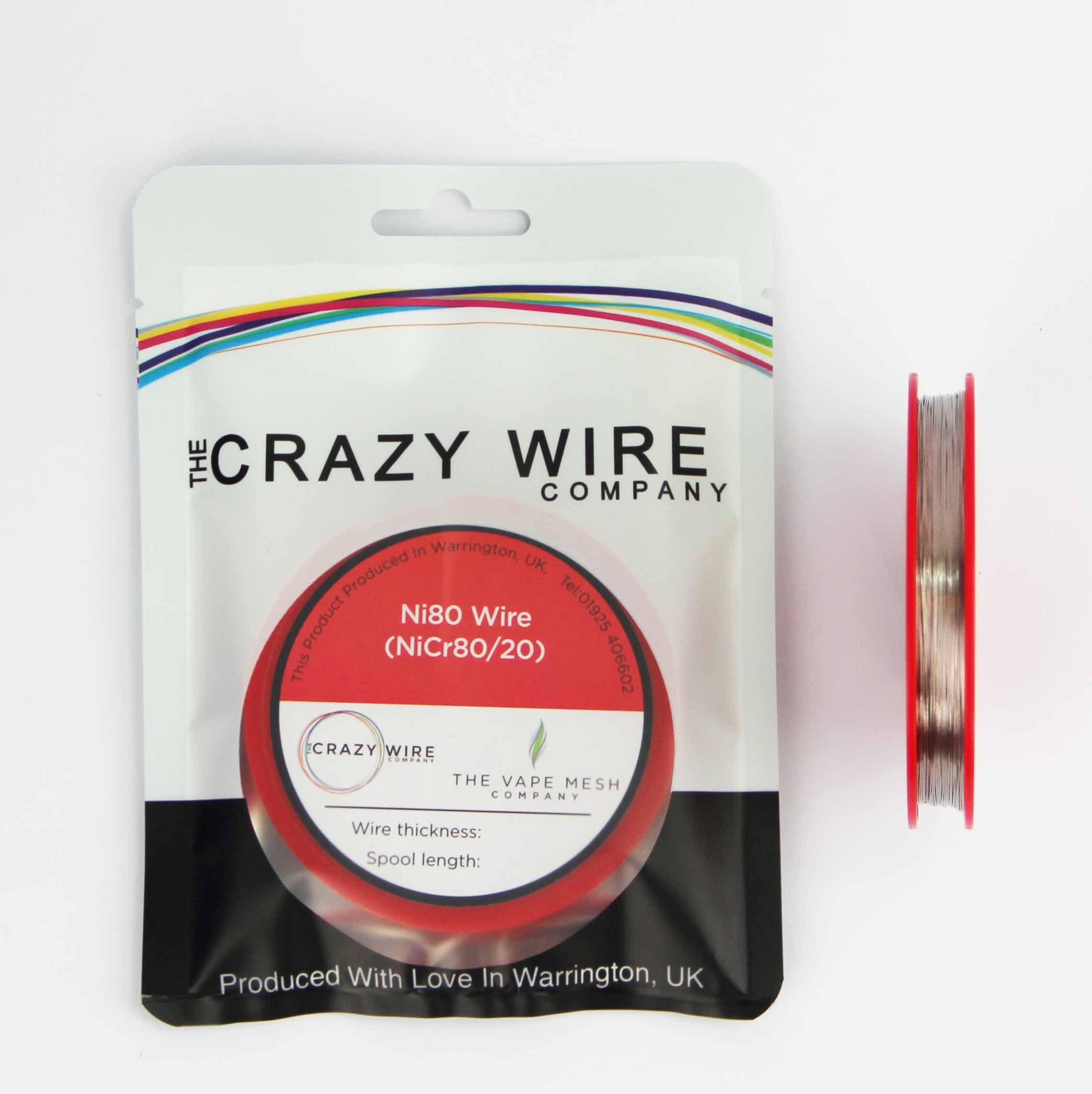

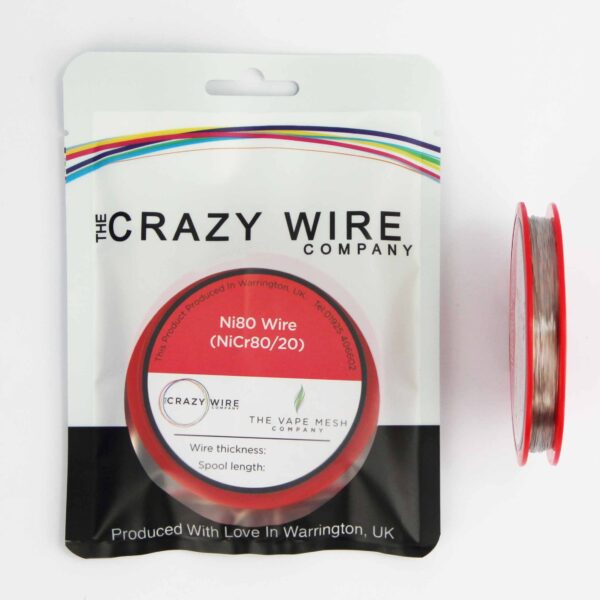

0.3mm Ni Cr Alloy Wire

The Crazy Wire Company are best know as suppliers of top quality ni cr alloy wire. We have enormous stock levels at all times, as we use this wire to weave our marine grade woven mesh products. Our brilliant staff are experts in producing our spools of round wire on our 6 rapid action winding machines. All spools are produced to carry a little extra length to make up for any waste when handling the product.

The 0.3mm (29 AWG) Ni80 Ni Cr alloy resistance wire is a high-quality product designed for diverse applications requiring durable and efficient conductive materials. Its superior resistance properties make it particularly well-suited to a variety of industrial and domestic tasks. This nickel/chromium alloy wire is primarily made of nickel (Ni) and chromium (Cr). Its excellent heat resistance and durability make the Ni80 Ni Cr alloy ideal for high-temperature applications. Thus, it is suitable for applications such as home appliances, electric heating elements, and specialised industrial equipment. 29 AWG wire is thin and strong, making it versatile for a variety of uses. Anti-corrosive properties mean it resists oxidation and other forms of wear, ensuring longevity and reliability. This wire’s high electrical conductivity and robust construction ensure consistent performance in various settings.

Key product details:

- Diameter – 0.3mm (300 Micron – 29 AWG)

- Ohms/m – 15.69

- Technical Specification:

- Ni – Rest

- Cr – 20.0 – 23.0

- Fe – <1.0

- Max Continuous Service Temp Of Element – 1200

- Micrographic Structure – Austenite

- Magnetic Properties – Nonmagnetic

- Electrical resistance is high

- Corrosion resistance is high

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

We do not only offer Ni80 round wire. We also have a huge range of KA1 and stainless steel round wire in immediate stock too.

Ribbon wire and flat wire are stocked for immediate dispatch too.

FAQs About This Wire

What Does Nichrome Wire Do?

Nichrome wire, also known as nickel-chromium (NiCr) wire, is a type of resistance wire that is commonly used in heating elements and electrical resistance heating applications. When an electrical current is passed through the wire, it generates heat due to its resistance to the flow of electricity. This makes it ideal for use in a wide range of heating applications, including heating elements for ovens, kilns, and furnaces, as well as for heating liquids, gases, and solids.

In addition to its heating properties, nichrome wire is also known for its high resistance to oxidation and corrosion, as well as its ability to maintain its mechanical and electrical properties at high temperatures. This makes it well suited for use in high-temperature applications, such as in the manufacture of thermocouples and other temperature-sensing devices.

When To Use Nichrome Wire?

Nichrome wire is used in a wide range of applications where reliable heating and high resistance to temperature and environmental conditions are required. Some common examples include:

- Heating elements: Nichrome wire is widely used as a heating element in a variety of appliances and equipment, such as electric stoves, ovens, kilns, furnaces, and space heaters.

- Thermocouples: Nichrome wire is used in the manufacture of thermocouples, which are temperature-sensing devices used to measure temperature in a variety of applications, including industrial processing, HVAC systems, and medical equipment.

- Electrical resistance heating: Nichrome wire is used in electrical resistance heating applications, such as in the heating of liquids, gases, and solids, as well as in the manufacturing of heat treatment equipment.

- Electronic components: Nichrome wire is used in the manufacture of various electronic components, such as fusible resistors and resistive heating elements in electric vehicles.

How Does Nichrome Wire Work?

Nichrome wire works by generating heat due to its resistance to the flow of electricity. When an electrical current is passed through the wire, the flow of electrons is impeded by the resistance of the wire, causing the wire to heat up. This is because the energy that is not converted into useful work is instead transformed into heat. The heating of the wire is proportional to the current passing through it, so by controlling the current, it is possible to control the amount of heat generated by the wire.

The resistance of the nichrome wire is determined by its composition and cross-sectional area. The composition of the wire is carefully chosen to provide the desired resistance and temperature stability, while the diameter of the wire is chosen to provide the desired resistance per unit length. By controlling the resistance and cross-sectional area of the wire, it is possible to produce a heating element that provides a precise and controlled amount of heat for a wide range of applications.

Why Does Nichrome Wire Heat Up?

Nichrome wire heats up because of the electrical resistance in the material. When an electric current is passed through the wire, the electrons collide with the lattice of the metal atoms, which causes the energy from the electrical current to be converted into heat. This process is known as electrical resistance heating, and it is the basic principle behind the operation of electrical heating elements, such as those found in electric heaters, toasters, and soldering irons.

The resistance of a wire depends on several factors, including the material of the wire, its cross-sectional area, and its length. Nichrome wire is commonly used for heating elements because it has a high resistance and a relatively low temperature coefficient of resistance, which means that its resistance does not change significantly as it heats up. This allows the wire to maintain a constant temperature, making it an ideal material for use in heating elements.

Check out our blog ‘what is nichrome‘ for more information on ni80 wire in general. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.