Description

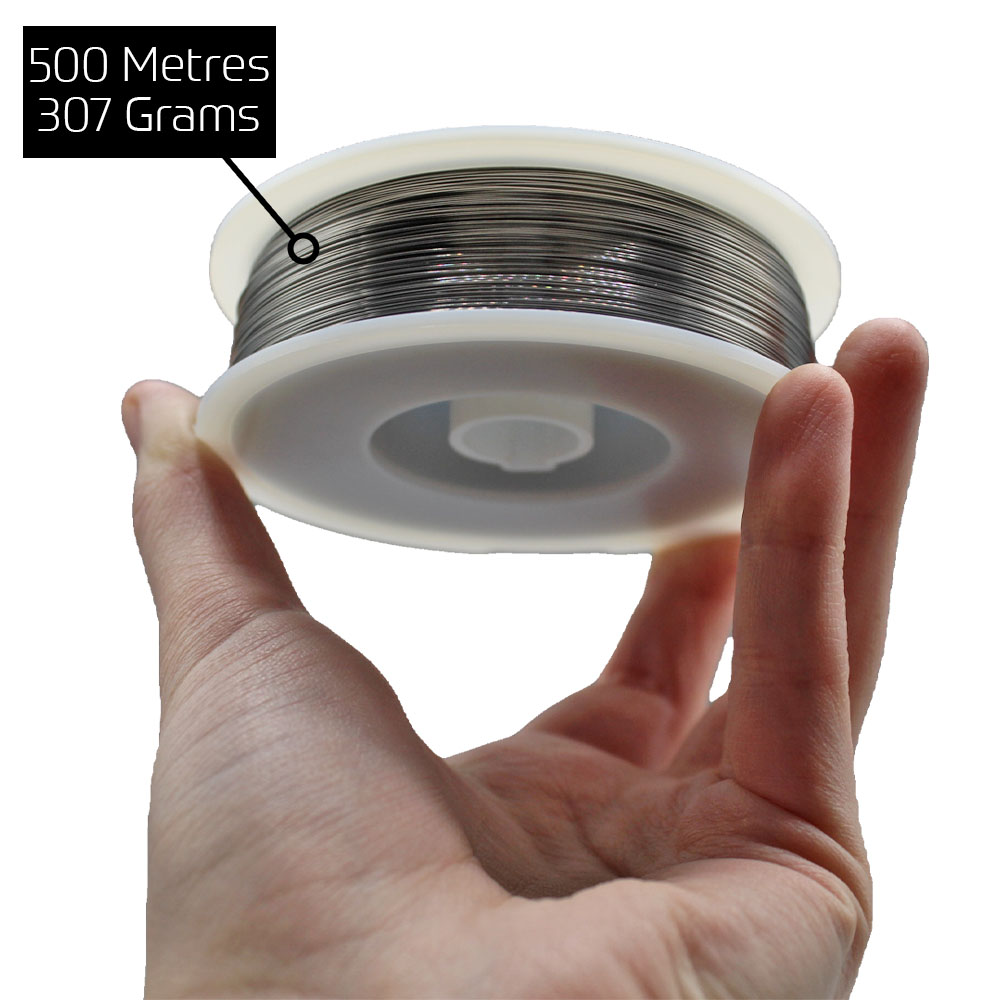

KA1 FeCrAl Wire

The Crazy Wire Company are best known and long established as Europe’s preferred suppliers of top quality KA1 FeCrAl wire. We have enormous stock levels at all times as we use this wire to weave our mesh products.

0.28mm FeCrAl A1 wire is a type of heating wire made of an iron-chromium-aluminium alloy. The wire has a diameter of 0.28mm, which is commonly used in applications that require a low to moderate heating load. FeCrAl A1 wire is known for its high electrical resistance, high-temperature resistance, and good oxidation resistance, which make it suitable for use in heating elements, resistors, and other high-temperature applications. The wire is also easy to work with and can be easily shaped and bent into different configurations. FeCrAl A1 wire is commonly used in various heating applications, including electric ovens, toasters, water heaters, and industrial furnaces, as well as in the manufacturing of heating coils and resistors.

Technical Specification:

- Diameter – 0.28mm (280 Micron – 30 AWG)

- Ohms/ft – 22.75

- C = Min – 0% Max – 0.08%

- Si = Min – 0% Max – 0.7%

- Mn = Min – 0% Max – 0.4%

- Cr = Min – 20.5% Max – 23.5%

- Al = Nominal Comp – 5.8% – Min – 0% – Max – 0%

- Fe = Balance

Available KA1 Options:

- 1.15mm (17 AWG) – 1.35 ohms/m

- 1.02mm (18 AWG) – 1.77 ohms/m

- 0.9mm (19 AWG) – 2.15 ohms/m

- 0.8mm (20 AWG) – 2.84 ohms/m

- 0.7mm (21 AWG) – 3.58 ohms/m

- 0.6mm (22 AWG) – 4.94 ohms/m

- 0.65mm (22 AWG) – 4.26 ohms/m

- 0.64mm (22 AWG)

- 0.5mm (24 AWG) – 7.11 ohms/m

- 0.55mm x 0.1mm – 26.05 ohms/m

- 0.55mm (23 AWG) – 5.96 ohms/m

- 0.4mm (26 AWG) – 11.46 ohms/m

- 0.48mm (25 AWG) – 7.79 ohms/m

- 0.45mm (25 AWG) – 8.93 ohms/m

- 0.42mm (26 AWG) – 10.6 ohms/m

- 0.3mm (29 AWG) -19.89 ohms/m

- 0.38mm (27 AWG) – 12.79 ohms/m

- 0.37mm (27 AWG) – 13.26 ohms/m

- 0.35mm (27 AWG) – 14.69 ohms/m

- 0.34mm (28 AWG) -15.15 ohms/m

- 0.32mm (28 AWG) -17.46 ohms/m

- 0.2mm (32 AWG) – 46.11 ohms/m

- 0.28mm (30 AWG) – 22.75 ohms/m

- 0.27mm (30 AWG) – 24.86 ohms/m

- 0.25mm (30 AWG) – 29.29 ohms/m

- 0.23mm (31 AWG) – 34.36 ohms/m

- 0.21mm (32 AWG) – 40.44 ohms/m

- 0.1mm x 0.2mm – 71.83 ohms/m

- 0.1mm (38 AWG)

- 0.18mm (33 AWG) – 56.98 ohms/m

- 0.17mm (34 AWG) – 62.57 ohms/m

- 0.15mm (34 AWG) – 82.52 ohms/m

- 0.13mm (36 AWG) – 107.87 Ohms/m

- 0.12mm (36 AWG)

- 0.09mm (39 AWG) – 228.40 ohms/m

- 0.08mm (40 AWG)

- 0.07mm (41 AWG)

- 0.06mm (42 AWG) – 496 ohms/m

- 0.05mm (44 AWG) – 577 ohms/m

Why Use The Crazy Wire Company

- Quality of products: The Crazy Wire Company always offer high-quality products that meet industry standards and customer expectations.

- Selection: We offer a wide variety of wire products and sizes to meet the diverse needs of our customers. We have more than 600 products available through our site and counting.

- Price: We always offer the best value possible. Our wires are available as part of our major weaving processes, so it is bought at the best possible rate.

- Availability: Our products are kept in house and are ready to ship immediately.

- Customer service: Our experienced staff help our customers feel confident in their purchases and provide assistance when required.

What Else Is Available?

We do not only offer KA1 round wire. We also have a huge range of stainless steel wire and Ni80 round wire in immediate stock too.

Ribbon wire and flat wire are stocked for immediate dispatch too.

FAQs About This Wire

Why Do Material And The Thickness Of A Wire Affect Resistance?

The material and thickness of a wire affect its resistance because they impact the flow of electrons through the wire, which is what causes electrical resistance.

The material of the wire affects its resistance because different materials have different resistivity values, which is a measure of how much they resist the flow of electrons. For example, materials like copper and Aluminium have low resistivity values, which means that they have a low resistance to electrical current flow, while materials like nichrome and tungsten have high resistivity values, which means that they have a higher resistance to electrical current flow. Therefore, wires made of materials with high resistivity values will have a higher resistance to electrical current flow than wires made of materials with low resistivity values.

The thickness of the wire affects its resistance because it impacts the cross-sectional area of the wire, which in turn affects the amount of space available for electrons to flow through. A thicker wire has a larger cross-sectional area, which means that there is more space available for electrons to flow through, resulting in a lower resistance. Conversely, a thinner wire has a smaller cross-sectional area, which means that there is less space available for electrons to flow through, resulting in a higher resistance.

How Do I Cut Resistance Wire?

Resistance wire can be cut using a variety of cutting tools, depending on the wire gauge and material. Here are some general tips for cutting resistance wire:

1. Use a wire cutter or diagonal pliers that are designed for cutting wires. These tools have sharp blades that are specifically designed to cut through wires cleanly and without damaging the wire.

2. Use a cutting tool that is appropriate for the wire gauge and material. For example, thicker wires may require a heavier-duty cutter, while softer materials like nickel-chromium may require a cutter with a serrated blade to prevent slipping.

3. Make sure the cutting tool is sharp and clean. Dull or dirty cutting tools can damage the wire and result in an uneven or jagged cut.

4. Mark the wire at the point where you want to cut it using a marker or other type of indicator. This will help ensure that you cut the wire to the desired length.

5. Use the cutting tool to make a clean, straight cut through the wire at the marked point. Apply firm, even pressure to the cutting tool, and avoid twisting or bending the wire during the cutting process.

6. After cutting the wire, use a file or sandpaper to smooth any rough edges or burrs that may have been created during the cutting process.

What Are The Applications Of Resistance Heating?

Resistance heating has a wide range of applications across various industries and settings. Here are some common applications of resistance heating:

1. Heating elements: Resistance wire is often used as heating elements in a wide range of appliances, including electric stoves, water heaters, space heaters, ovens, and dryers.

2. Industrial heating: Resistance heating is used in many industrial processes, including heat treating, sintering, and brazing. It is also used in manufacturing processes for products such as glass, ceramics, and semiconductors.

3. Medical equipment: Resistance heating is used in medical applications such as sterilization equipment and warming devices for blood and other fluids.

4. Aerospace: Resistance heating is used in aerospace applications such as de-icing systems for aircraft and spacecraft.

5. Laboratories: Resistance heating is used in laboratory applications such as thermal analysis, where samples are heated and cooled to measure their thermal properties.

6. Food industry: Resistance heating is used in the food industry to cook, bake, and preserve food products. It is also used in commercial equipment such as fryers, grills, and steam tables.

Why Are Alloys Used In Electrical Heating Devices ?

Alloys are commonly used in electrical heating devices because they have certain properties that make them well-suited for these applications. Here are a few reasons why alloys are used in electrical heating devices:

1. High electrical resistance: Many alloys have a higher electrical resistance than pure metals, which makes them well-suited for use in heating elements. When an electrical current is passed through an alloy with high resistance, it generates heat, which can be used for heating applications.

2. High melting point: Alloys such as Nichrome and KA1 have high melting points, which allows them to withstand the high temperatures that are generated during heating. This makes them suitable for use in high-temperature applications such as furnaces, ovens, and electric water heaters.

3. Corrosion resistance: Some alloys are more resistant to corrosion than pure metals, which makes them more durable and longer-lasting in harsh environments. This is particularly important in applications where the heating element may be exposed to water or other corrosive substances.

4. Ductility: Many alloys are ductile and can be easily formed into different shapes, which makes them suitable for use in a wide range of heating elements with different sizes and shapes.

Overall, the use of alloys in electrical heating devices is beneficial because they offer a combination of properties that make them well-suited for these applications, including high electrical resistance, high melting point, corrosion resistance, and ductility.

The Crazy Wire Company is a leading UK based supplier of nichrome, FeCrAl, and stainless steel wires. We specialise in rapid delivery to any location around the country. Our factory is located in Warrington, which is the historic home of the UK’s wire industry.

Check out our blog ‘everything that you need to know about wires’ for more information on resistance wire in general. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

We also offer similar products through our highly popular eBay store, check us out there too.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

Reviews

There are no reviews yet.